Coating

A coating whether for your application or as an assembly ease, automatic assembly or dynamic application – you will find we have the appropriate solution for every application. Would you like further information on our standard types?

You will find an overview here:

- Longterm Cleaning ”LABS-free”

- Silicone Coating

- Fluorination

- Talcum Powder Coating

- Molybdenum Disulphide Coating

- Polysiloxane Coating

- 3K-Coating

- PTFE Coatings

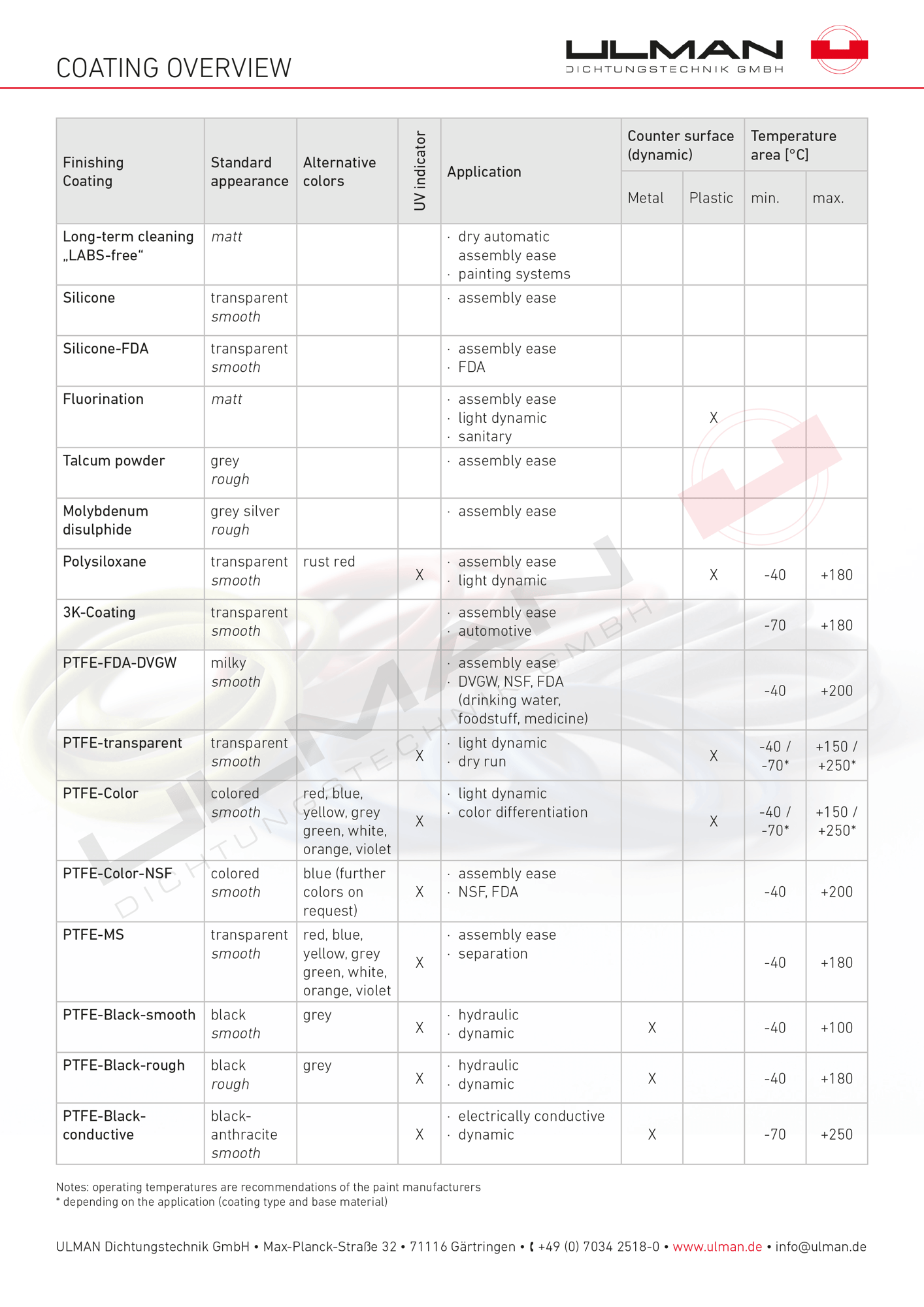

Coating Overview

We can offer you further coating variants. Please contact our engineers for further information, they are more than happy to support you.

Longterm Cleaning ”LABS-free”

”LABS” stands for free of adhesive-repelling substances. These are resources that are used for the manufacturing of O-rings, but may cause a negative effect on the application, for example in the automotive industry. Visible differences can occur on the painted surface, these prevent an evenly wetting effect.

Depending on the material, a cleaning of the O-ring surface is insufficient. Through a special cleaning process, all adhesive-repelling substances i.e. silicones will be removed from the O-ring. Thereby the entire material will be permanently cleaned up to the O-ring core. The physical properties of the elastomer will not be altered after the cleaning process.

”LABS-free” O-rings must be stored and handled in a special packaging after the cleaning process.

Cleaned parts comply, amongst others to the VW test specification 3.10.7 and are also well suited for dry automatic assembly.

Silicone Coating

By reeling of a silicone based lubricant oil the assembly forces are significantly reduced. The coating has a good adhesion and creates a smooth surface. However, this coating tends to let the O-rings stick together and is therefore not suitable for automatic separation.

Fluorination

Fluorination is not a coating process, but a surface treatment process for plastic and elastomer components. The components get exposed to a fluorine gas mixture where the surface will be chemically modified and the hydrogen embedded into molecular chains of the base material is partially replaced by fluorine.

As a result of the increased surface energy, there is an improvement on friction reduction, wettability and adhesion as well as reduced permeation of the base material. This allows seals to be separated easily and fewer particles of dirt adhere to the surface. The main application for fluorinated parts is the automatic assembly. It can also be used for slow dynamic applications in which the stick-slip effect and friction properties are reduced.

Since the penetration depth of the fluorine atoms into the base material is only in the molecular range, the properties and dimensions of the substrate remain the same, even after any additional cleaning.

Talcum Powder Coating

In this surface finishing, a finest talcum powder will be reeled onto the surface of the O-rings. Thereby the O-rings can be easily automatically separated and assembled. This coating has only a low abrasion resistance and can lead to a contamination of the machine.

Molybdenum Disulphide Coating

High purity molybdenum disulphide (MoS2) will be reeled onto the surface of the O-rings. Thereby the O-rings can also be easily automatically separated and assembled. In a long term, the frictional force can be reduced by the incorporating of the lubricants into the mating surfaces. This coating also, has only a low abrasion resistance and can lead to a contamination of the machine.

Polysiloxane Coating

By applying water-soluble one-component coating for elastomeric parts with graphite contingents, share a good adhesion of the coating. The dry surface is ideal for automated assembly processes and has a sufficient dry lubrication property at low dynamic applications.

3K-Coating

An air-drying three-component, solvent-based anti-friction coating for friction reduction of elastomer parts.

It is a transparent, dry and thin lubricating layer that is mainly used for assembly ease.

Frequently used in the automotive sector and media resistance to water, gasolines and mineral oils in general. It has a wide operating temperature range from -70°C to +180°C.

PTFE Coatings

A good adhesion of the powder is achieved by applying PTFE in water-soluble one-component coating for elastomeric parts on the clean and modified surface. The treated O-rings can still be automatically separated, feed and assembled very well, even after a prolonged storage.

PTFE Coatings reduce the pressing forces and are used as an assembly aid. They come in the most different variants depending on the application, further to the technical data sheets.