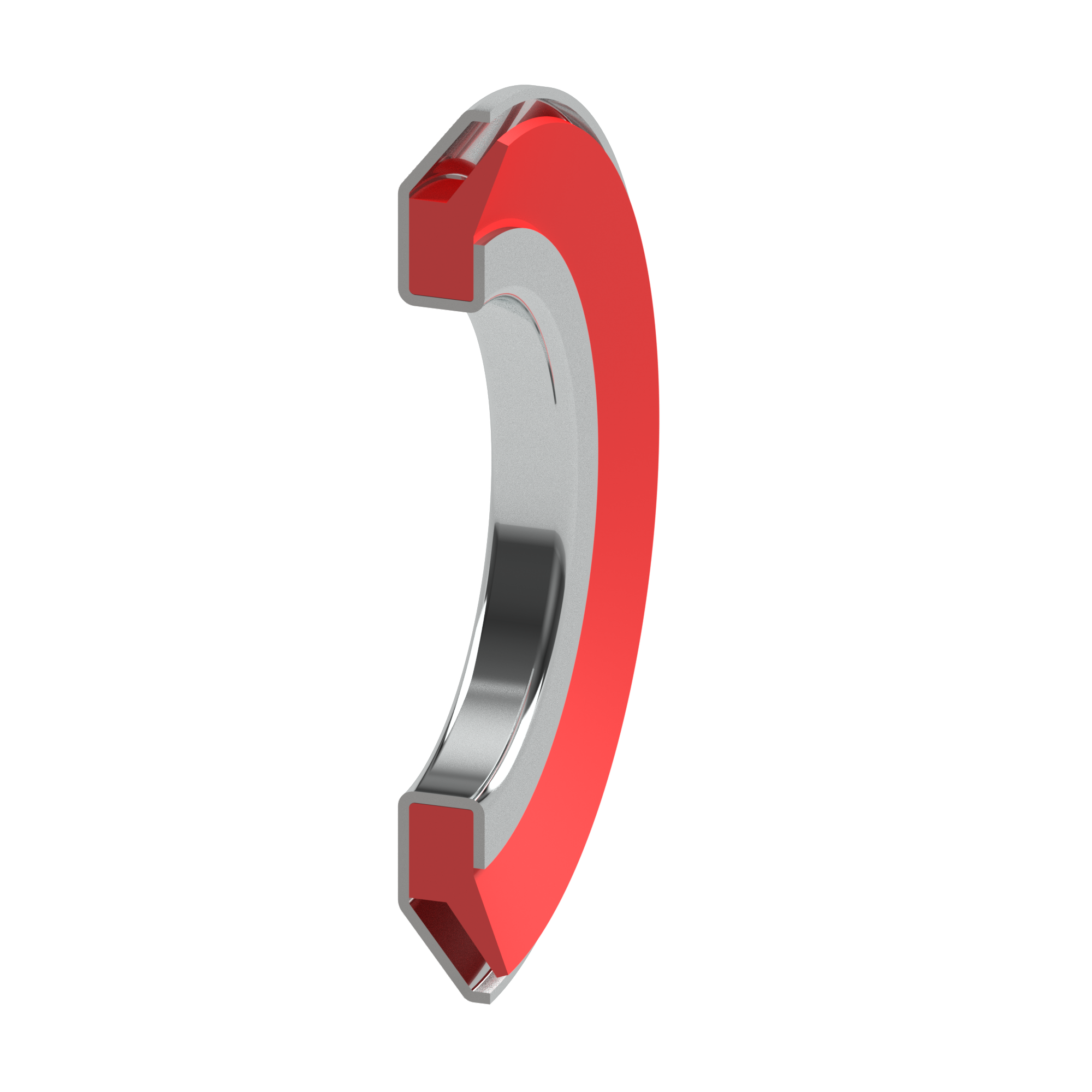

Rotary Seals Gamma Ring GB

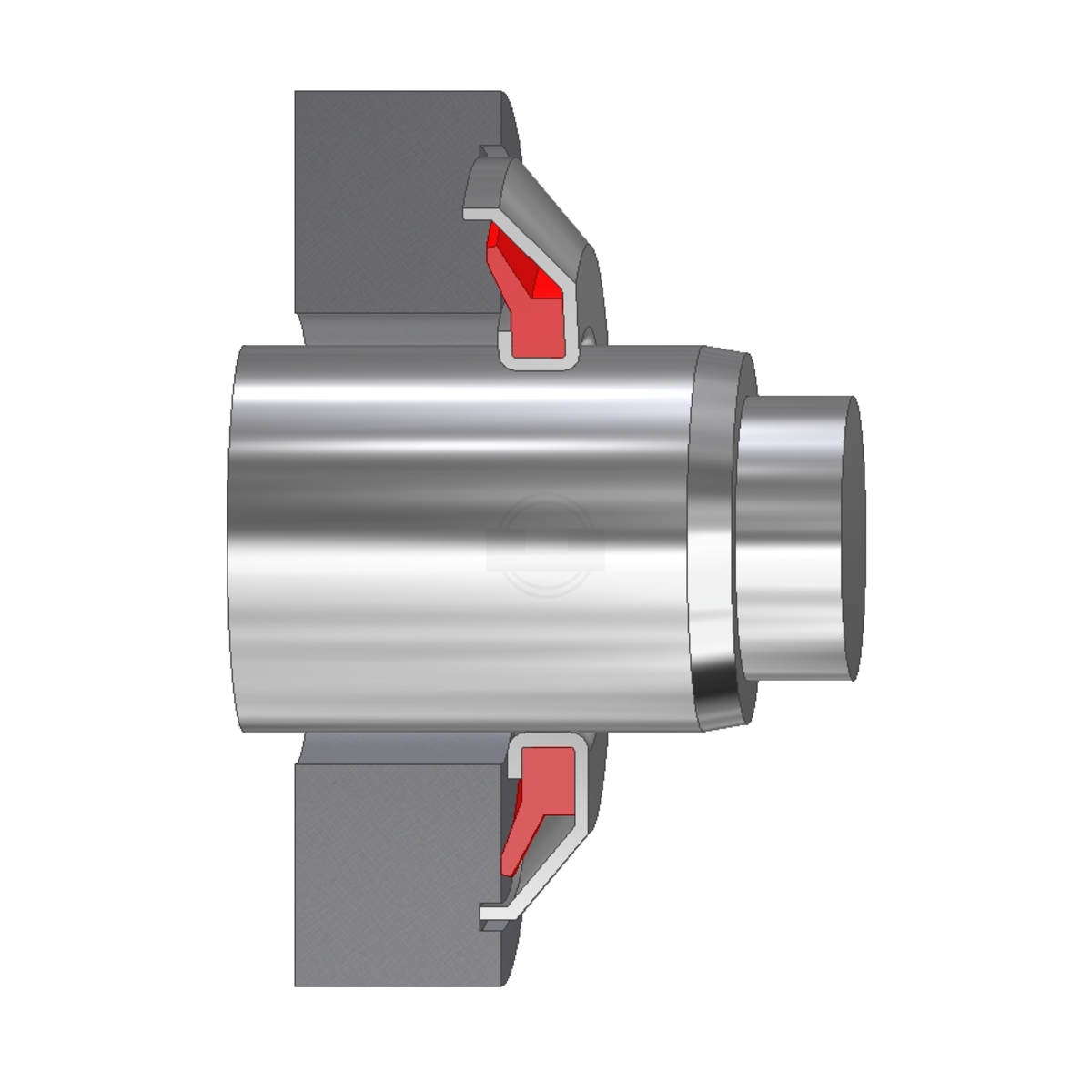

The Gamma Ring GB is an axial sealing, single-acting sealing element for non-pressurized shaft and bearing sealing applications against the intrusion of contamination and water spray from outside. The metallic fit on the inner diameter, ensures a secure grip on the shaft. Due to the extended metal ring of the Gamma Ring GB design, this guarantees good protection against coarse contamination.

In contrast to radial oil shaft seals, Gamma rings seal against the vertical arranged front surface. Metal casing comes in standard unalloyed carbon steel as well as stainless steel variants. Standard elastomer materials for the flexible seal lips are NBR and FKM. Further materials are available upon demand.

Gamma Ring GB

Technical values

Technology - General sealing topics, special constructions

Head of Engineering

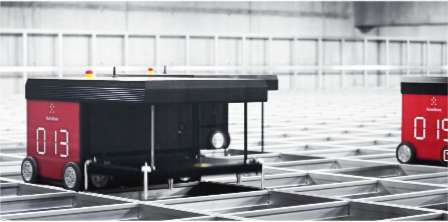

Our Logistics – Your Service

Innovative, environmentally friendly and efficient

In addition to innovative techniques, our logistics has 2,870 sqm of process surface. We have the world's first AutoStore storage system on two levels. Both grits are connected to each other by means of special lifters. In total, up to 31,000 containers can be stored in a very confined space. Due to this subdivision, up to 240,000 storage areas can be managed most efficiently.