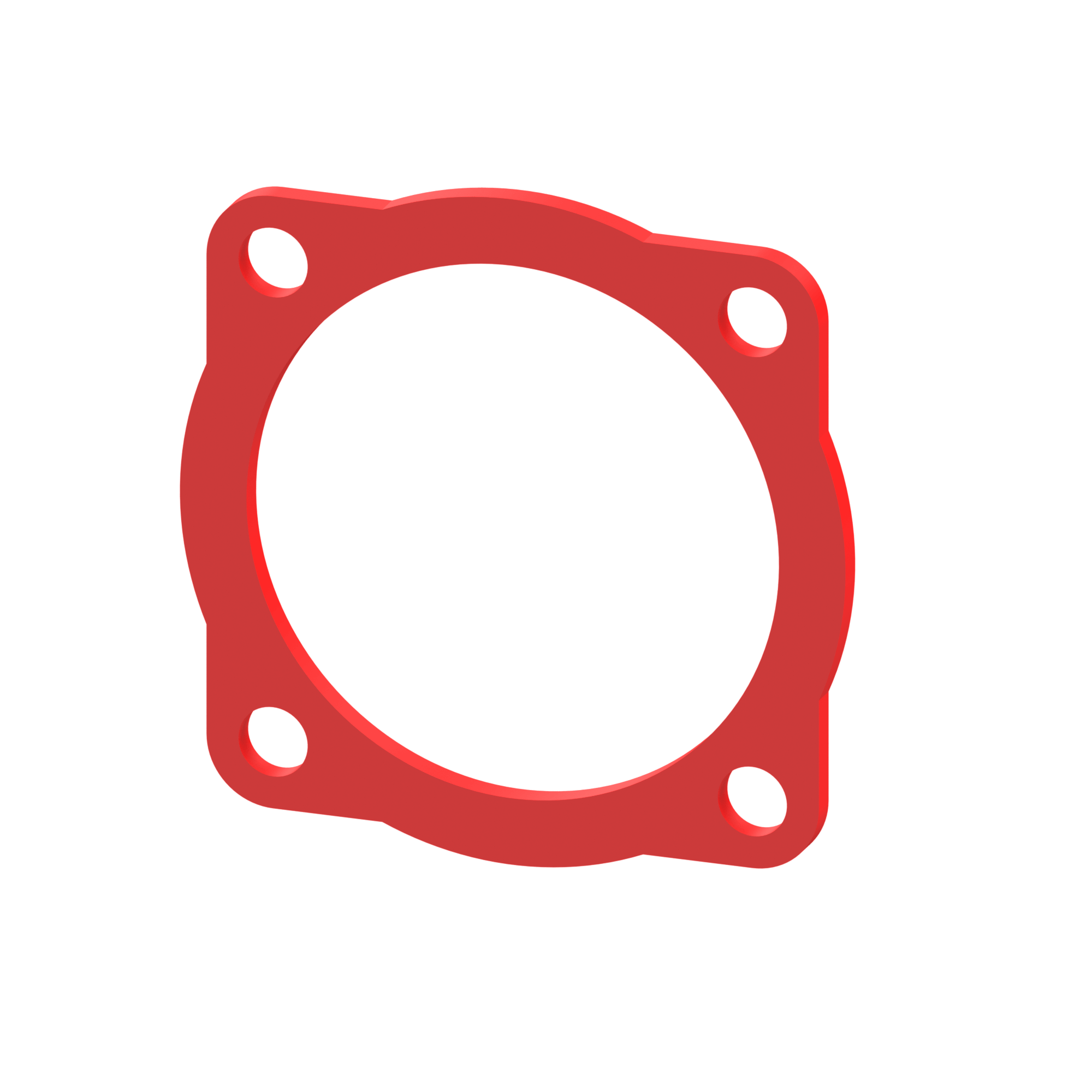

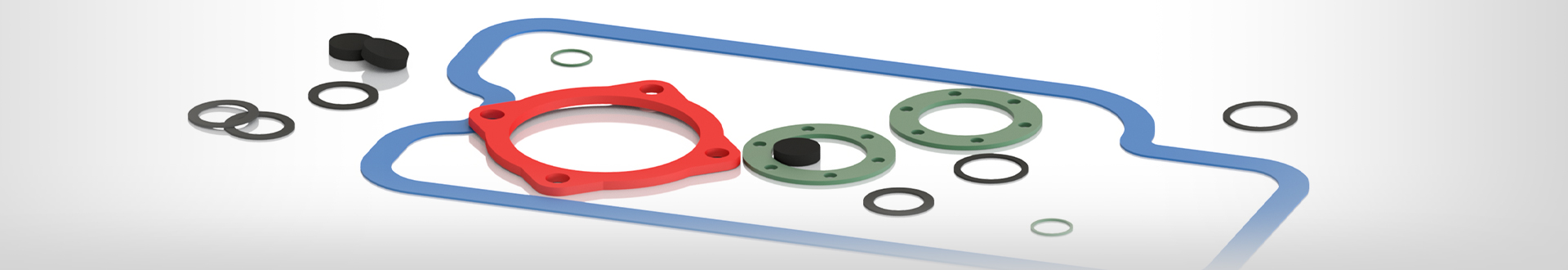

Static Seals Flat Gasket

Flat Gaskets parts are individually designed sealing elements, that can be specially manufactured according to customer specifications. A large variety of materials are available. Flat Gaskets can be produced in different techniques:

- punching

- waterjet cutting

- cut from tube

- production per injection moulding or compression method

Flat Gasket

Fields of application

static

dynamic

single acting

double acting

Linear

Rotating

oszilating

Main use

static sealing for specific applications

Materials

elastomers; fabric-based laminate; metal; plastics

Technical values

Materials

Pressure

up to 50 MPa

Temperature

-60°C / +200°C (material dependent)

Speed

-

Pressure

up to 50 MPa

Temperature

-200°C / +500°C (material dependent)

Speed

-

Pressure

up to 50 MPa

Temperature

-200°C / +300°C (material dependent)

Speed

-

Maximum values temperature, speed and pressure are simultaneously not applicable! The values vary in dependence of material and media. For technical queries please contact our application consultants – we have the right solution for you.

Downloads

Your contact person for

Technology - General sealing topics, special constructions

Mr. Andreas Raidt

Head of Engineering

Head of Engineering

Do you have any questions, ideas, or suggestions? We are more than happy to assist you with advice. In person, over the phone, or digitally.

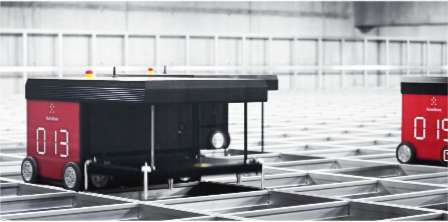

Our Logistics – Your Service

Innovative, environmentally friendly and efficient

In addition to innovative techniques, our logistics has 2,870 sqm of process surface. We have the world's first AutoStore storage system on two levels. Both grits are connected to each other by means of special lifters. In total, up to 31,000 containers can be stored in a very confined space. Due to this subdivision, up to 240,000 storage areas can be managed most efficiently.