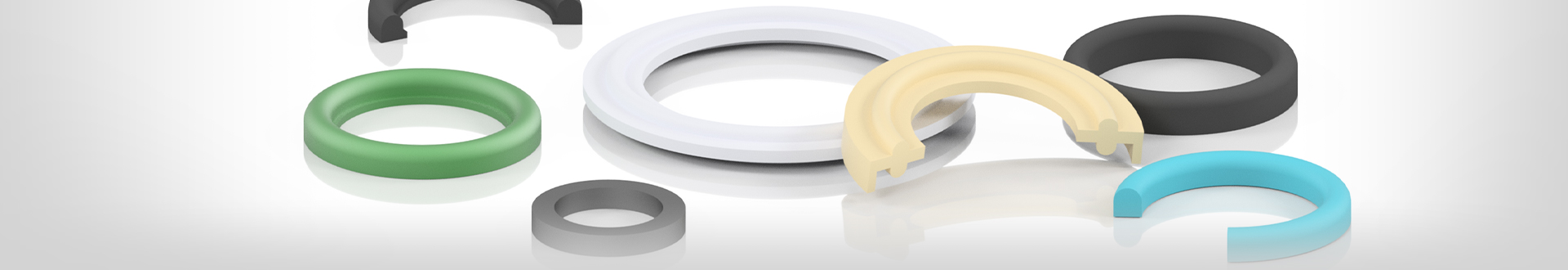

Static Seals M-ring

Standardized sealing for axial static applications in pipe screw joints.

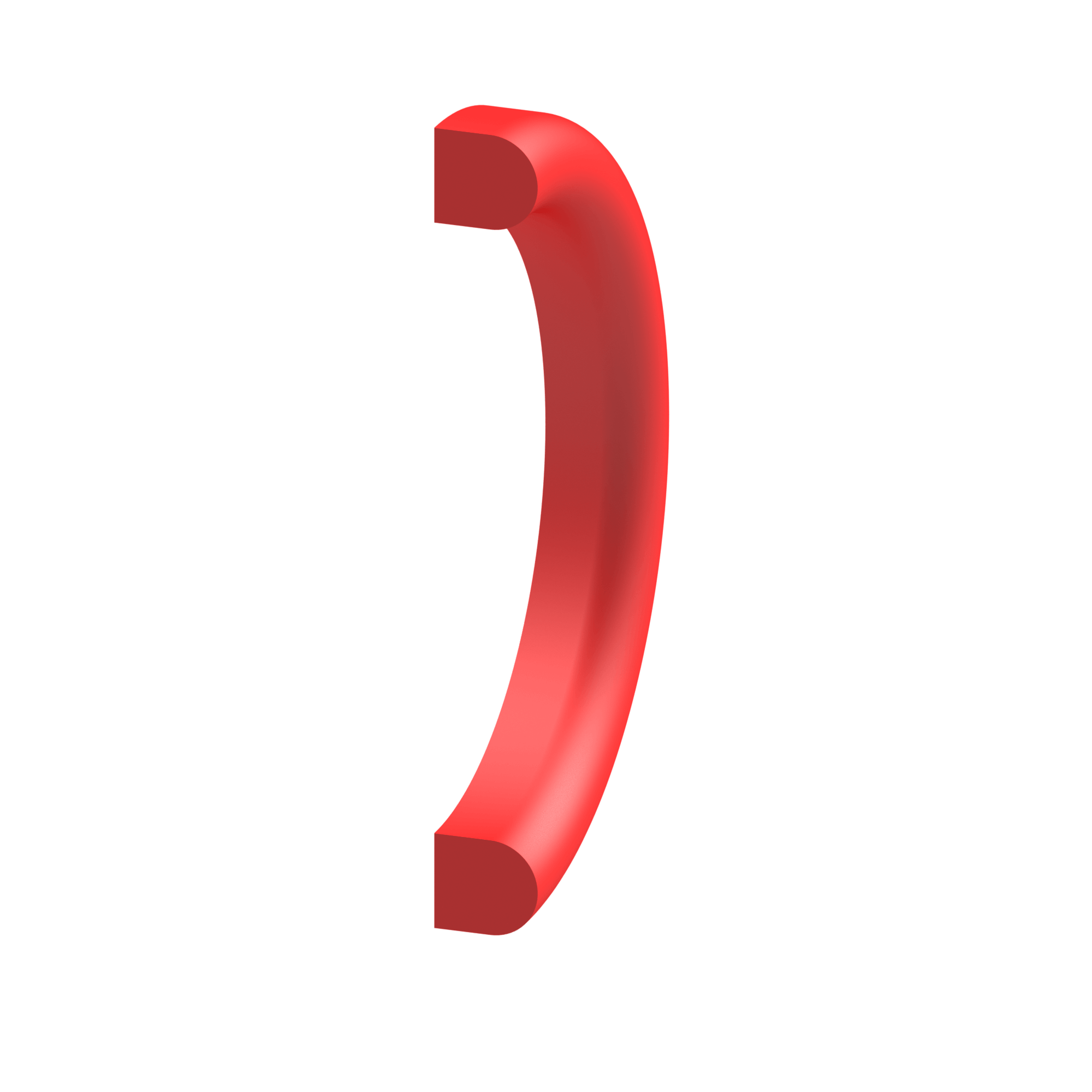

M-ring Type MA

For standardized pipe screw joints according to the DIN 11851 ...

Applications

static

dynamic

single acting

double acting

Linear

Rotating

oszilating

Main use

valves for the food industry

Materials

elastomers; PTFE

Technical values

Product details

Materials:

Pressure: up to 16 MPa

Temperature: -200°C / +260°C (material dependent)

Speed: -

Pressure: up to 16 MPa

Temperature: -30°C / +80°C (material dependent)

Speed: -

Pressure: up to 16 MPa

Temperature: -20°C / +200°C (material dependent)

Speed: -

Pressure: up to 16 MPa

Temperature: -40°C / +130°C (material dependent)

Speed: -

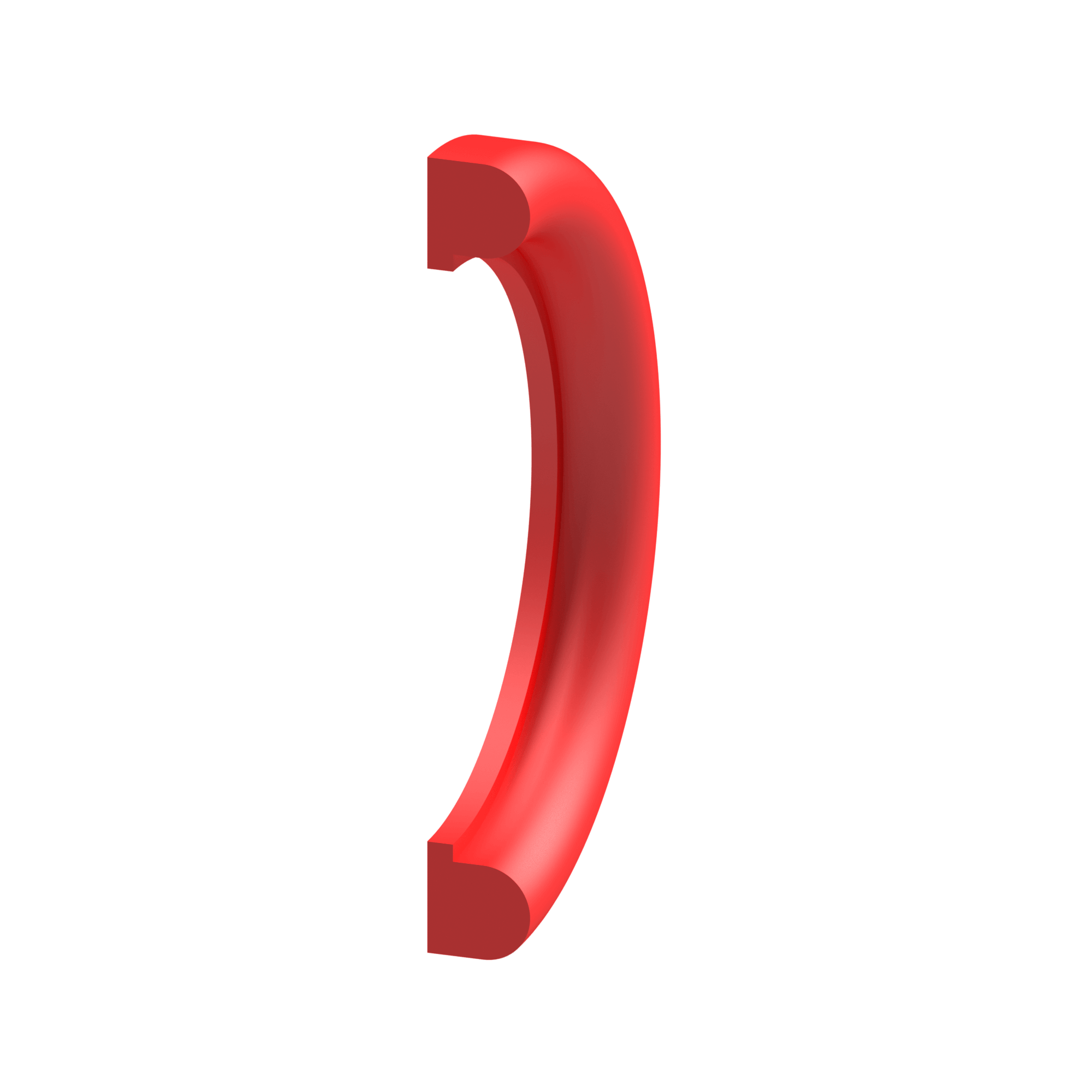

M-ring Type MC

For pipe screw joints likewise to the DIN 11851, with a raised design ...

Applications

static

dynamic

single acting

double acting

Linear

Rotating

oszilating

Main use

valves for the food industry

Materials

elastomers; PTFE

Technical values

Product details

Materials:

Pressure: up to 16 MPa

Temperature: -30°C / +80°C (material dependent)

Speed: -

Pressure: up to 16 MPa

Temperature: -20°C / +200°C (material dependent)

Speed: -

Pressure: up to 16 MPa

Temperature: -40°C / +130°C (material dependent)

Speed: -

Pressure: up to 16 MPa

Temperature: -200°C / +260°C (material dependent)

Speed: -

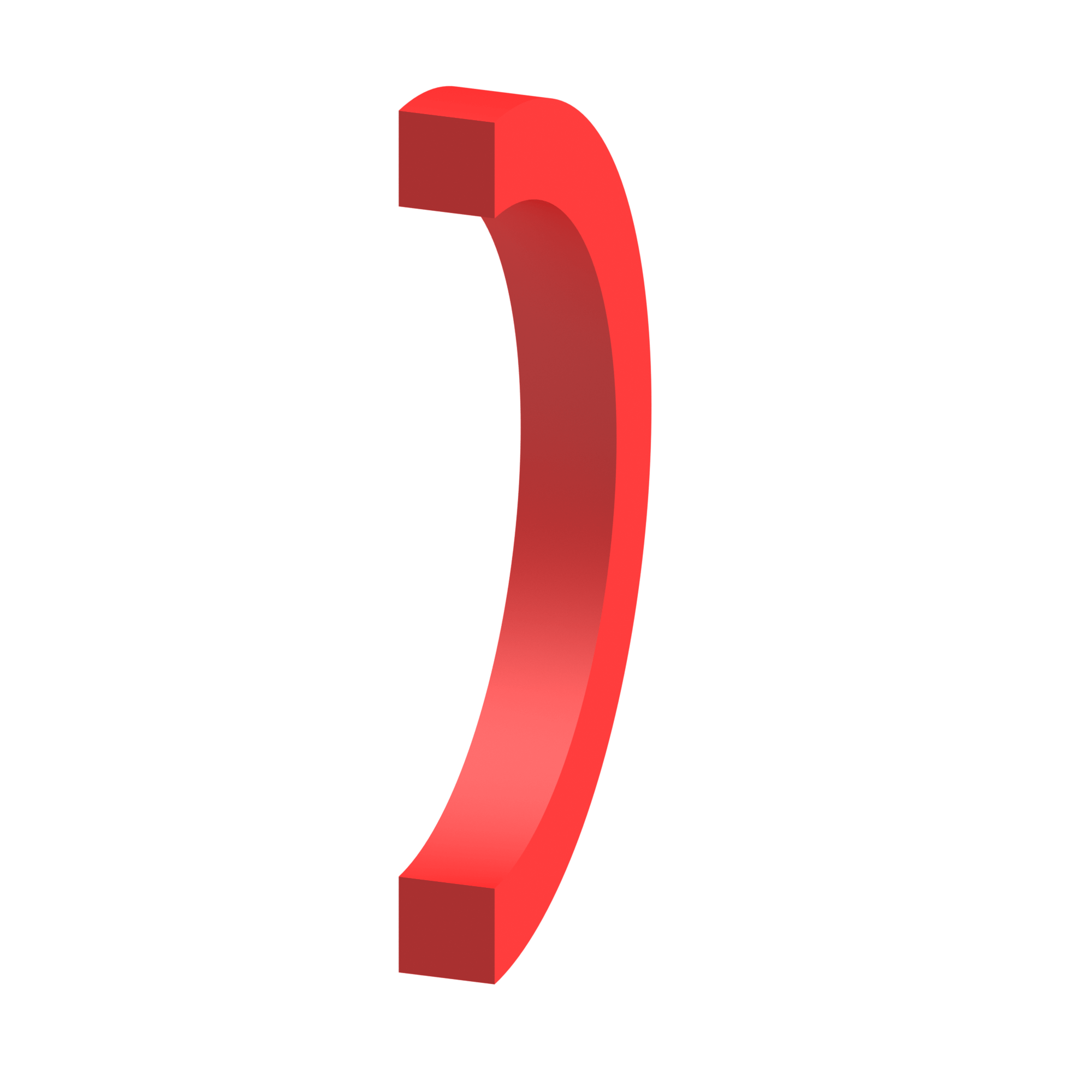

M-ring Type MB

For pipe screw joints likewise to the DIN 11851, with an inner collar ...

Applications

static

dynamic

single acting

double acting

Linear

Rotating

oszilating

Main use

valves for the food industry

Materials

elastomers; PTFE

Technical values

Product details

Materials:

Pressure: up to 16 MPa

Temperature: -30°C / +80°C (material dependent)

Speed: -

Pressure: up to 16 MPa

Temperature: -20°C / +200°C (material dependent)

Speed: -

Pressure: up to 16 MPa

Temperature: -40°C / +130°C (material dependent)

Speed: -

Pressure: up to 16 MPa

Temperature: -200°C / +260°C (material dependent)

Speed: -

M-ring Type MD / MF

Clamp sealing according to the DIN 32676 / ISO 2852, with or without an outer collar ...

Applications

static

dynamic

single acting

double acting

Linear

Rotating

oszilating

Main use

valves for the food industry

Materials

elastomers; PTFE

Technical values

Product details

Materials:

Pressure: up to 16 MPa

Temperature: -30°C / +80°C (material dependent)

Speed: -

Pressure: up to 16 MPa

Temperature: -20°C / +200°C (material dependent)

Speed: -

Pressure: up to 16 MPa

Temperature: -40°C / +130°C (material dependent)

Speed: -

Pressure: up to 16 MPa

Temperature: -200°C / +260°C (material dependent)

Speed: -

M-ring Type ME

SMS sealing for pipe fittings ...

Applications

static

dynamic

single acting

double acting

Linear

Rotating

oszilating

Main use

valves for the food industry

Materials

elastomers; PTFE

Technical values

Product details

Materials:

Pressure: up to 16 MPa

Temperature: -30°C / +80°C (material dependent)

Speed: -

Pressure: up to 16 MPa

Temperature: -20°C / +200°C (material dependent)

Speed: -

Pressure: up to 16 MPa

Temperature: -40°C / +130°C (material dependent)

Speed: -

Pressure: up to 16 MPa

Temperature: -200°C / +260°C (material dependent)

Speed: -

Your contact person for

Technology - General sealing topics, special constructions

Mr. Andreas Raidt

Head of Engineering

Head of Engineering

Do you have any questions, ideas, or suggestions? We are more than happy to assist you with advice. In person, over the phone, or digitally.

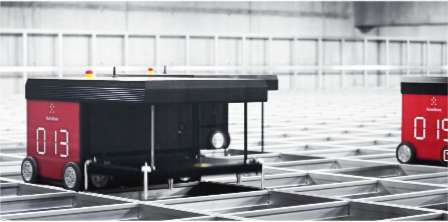

Our Logistics – Your Service

Innovative, environmentally friendly and efficient

In addition to innovative techniques, our logistics has 2,870 sqm of process surface. We have the world's first AutoStore storage system on two levels. Both grits are connected to each other by means of special lifters. In total, up to 31,000 containers can be stored in a very confined space. Due to this subdivision, up to 240,000 storage areas can be managed most efficiently.