Dynamic Seals Stuftef KS

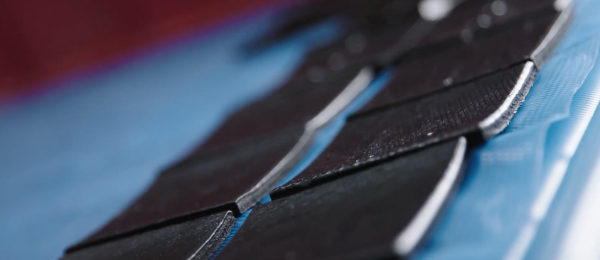

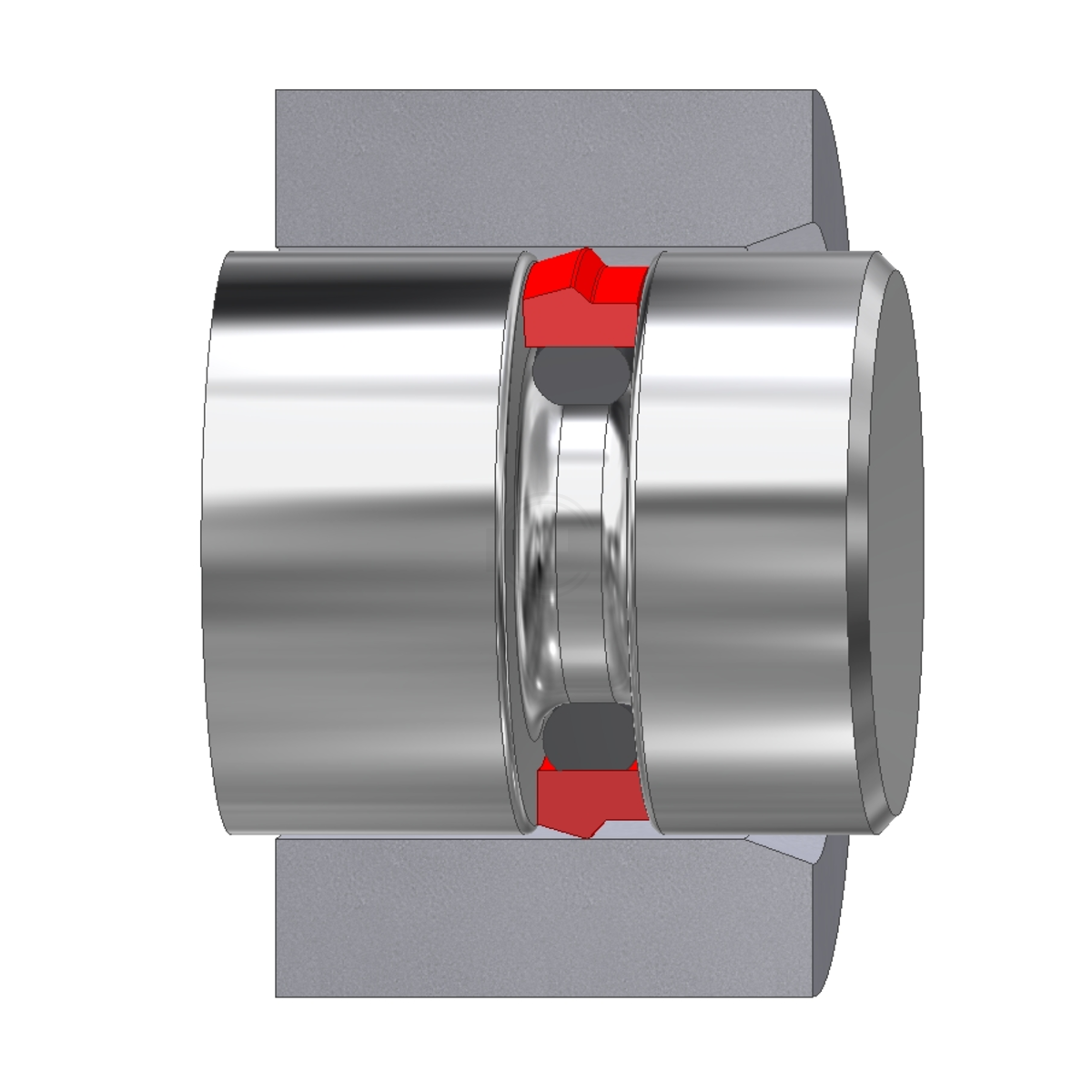

Stuftef KS is a single-acting sealing element which consists of a PTFE seal and an O-ring as preload element. Stuftef KS is an active sealing element and as the system pressure increases, the force on the sealing edge also increases. Due to the special geometry of Stuftef KS makes it possible for an adherent lubricating film on the rod to be conveyed back into the pressure chamber during the return stroke.

This is particularly suitable for hydraulic and pneumatic cylinders, fittings, presses and machine tools. Also suitable for tandem arrangement. The PTFE compound is filled with bronze or carbon graphite to improve the compressive strength. Further materials upon request. O-rings are available in a variety of different materials.

Stuftef KS

Technical values

Engineering - General sealing topics, special constructions

Our Logistics – Your Service

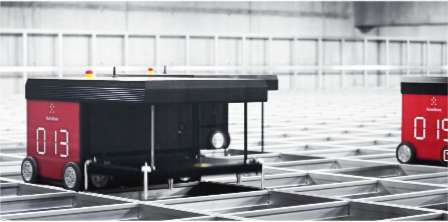

Innovative, environmentally friendly and efficient

In addition to innovative techniques, our logistics has 2,870 sqm of process surface. We have the world's first AutoStore storage system on two levels. Both grits are connected to each other by means of special lifters. In total, up to 31,000 containers can be stored in a very confined space. Due to this subdivision, up to 240,000 storage areas can be managed most efficiently.