Dynamic Seals U-cup N8

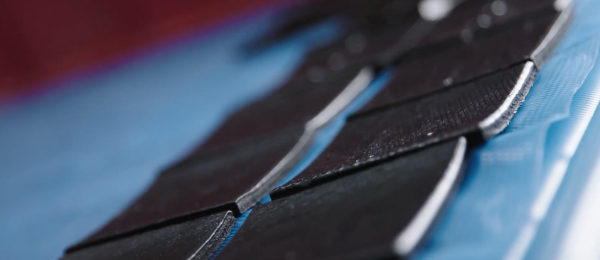

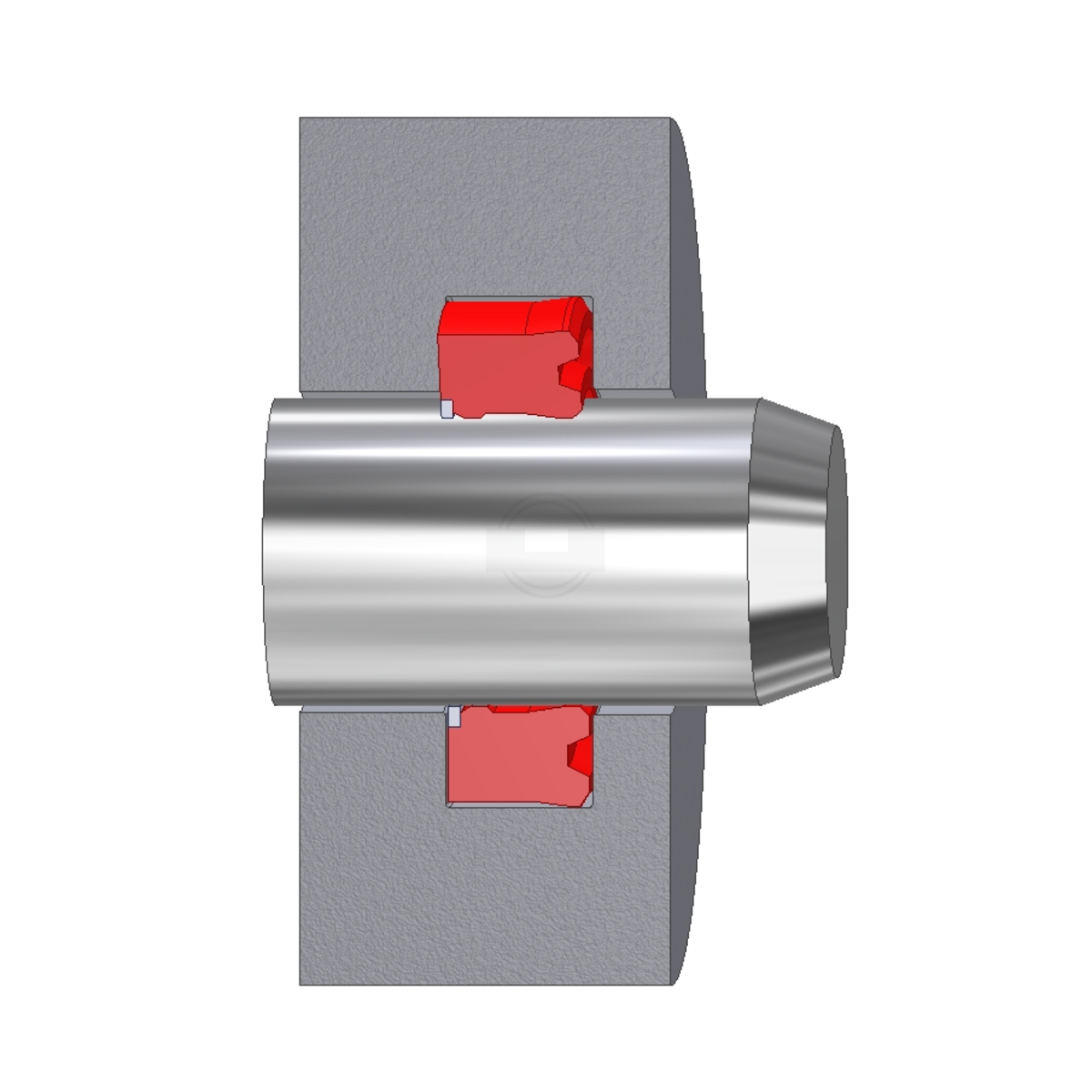

The U-cup N8 is a two-piece, single-acting sealing element and is available in polyurethane (TPU) with a integrated POM Back-up ring. U-cup seals are active sealing elements and as the system pressure increases, the force on the sealing lips also increases.

The U-cup N8 are used primary for hydraulic applications and has a particularly robust profil. The second sealing lip counters the stick-slip tendency. The integrated Back-up ring on the back of the seal prevents gap extrusion also at higher pressures. TPU makes these seals suitable as primary and secondary seals, due to the excellent abrasion resistance.

The standard TPU compound has a hardness of 93 Shore A. Compounds in a different hardness and/or color are available upon request.

U-cup N8

Technical values

Engineering - General sealing topics, special constructions

Our Logistics – Your Service

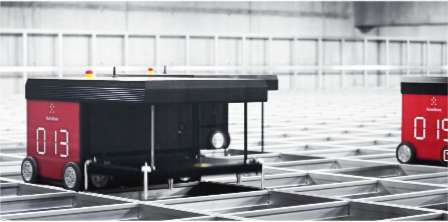

Innovative, environmentally friendly and efficient

In addition to innovative techniques, our logistics has 2,870 sqm of process surface. We have the world's first AutoStore storage system on two levels. Both grits are connected to each other by means of special lifters. In total, up to 31,000 containers can be stored in a very confined space. Due to this subdivision, up to 240,000 storage areas can be managed most efficiently.