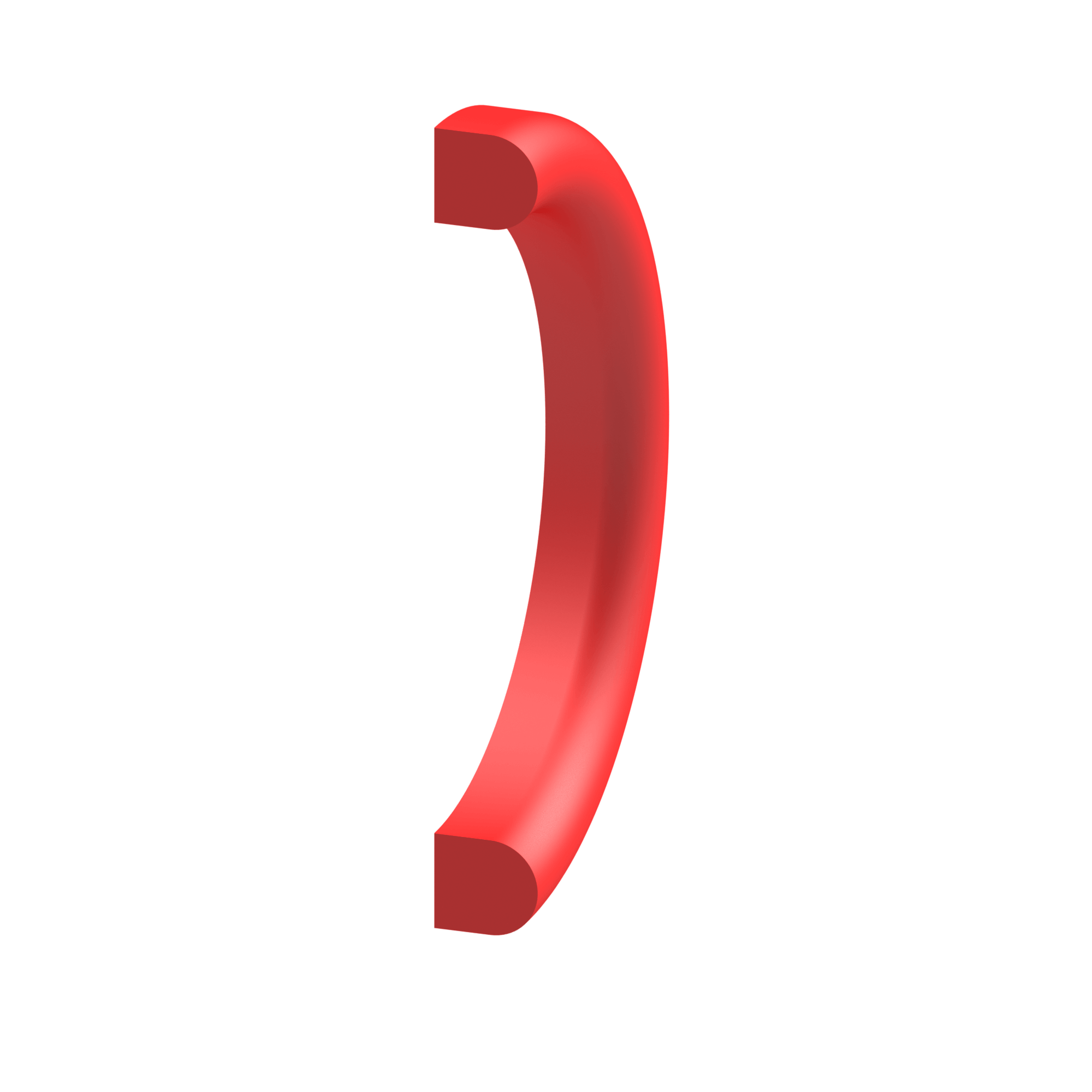

Static Seals M-ring Type MA

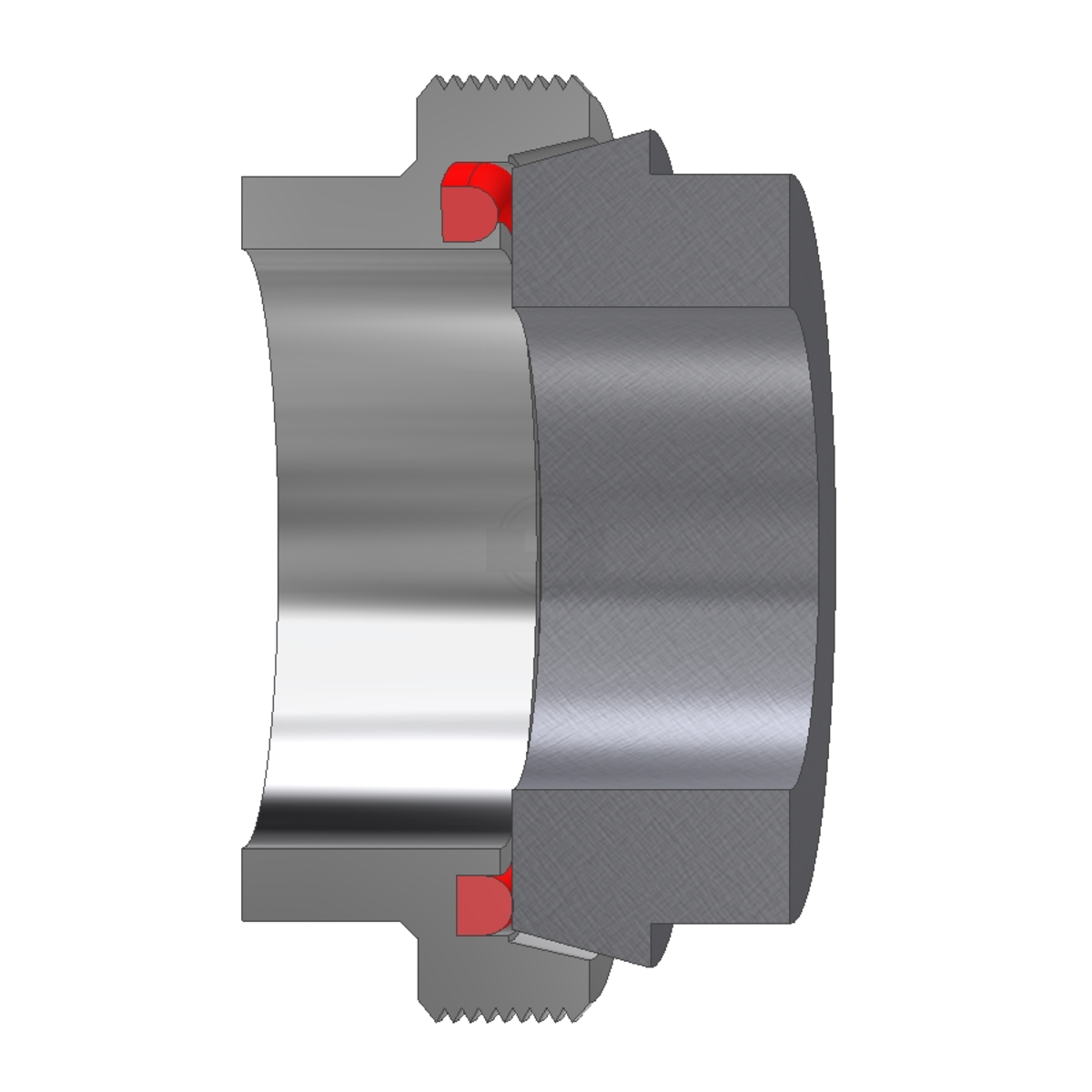

The M-ring type MA is an axial static sealing element for stainless steel fittings according to the DIN 11851 for the food industry. Diary pipe screw joints are available in a variety of common elastomer materials. The most common of these would be NBR, FKM, EPDM and PTFE.

Compounds comply with the Code of Federal Regulations (FDA-Food and Drug Administration) 21 CFR 177.2600 or 21 CFR 177.1550. Further compounds are available upon request i.e. with accordance to BfR recommendation XXI, USP Class VI and 3-A Sanitary Standards.

M-ring Type MA

Technical values

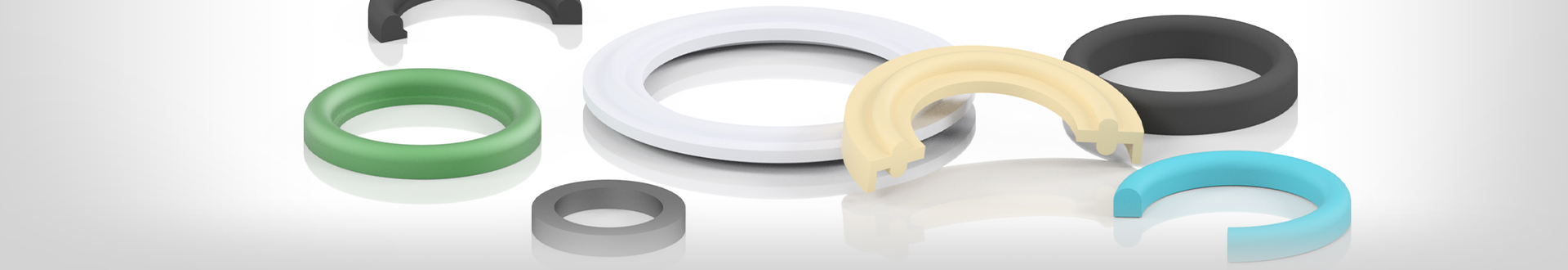

Technology - General sealing topics, special constructions

Head of Engineering

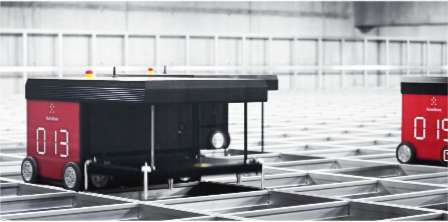

Our Logistics – Your Service

Innovative, environmentally friendly and efficient

In addition to innovative techniques, our logistics has 2,870 sqm of process surface. We have the world's first AutoStore storage system on two levels. Both grits are connected to each other by means of special lifters. In total, up to 31,000 containers can be stored in a very confined space. Due to this subdivision, up to 240,000 storage areas can be managed most efficiently.