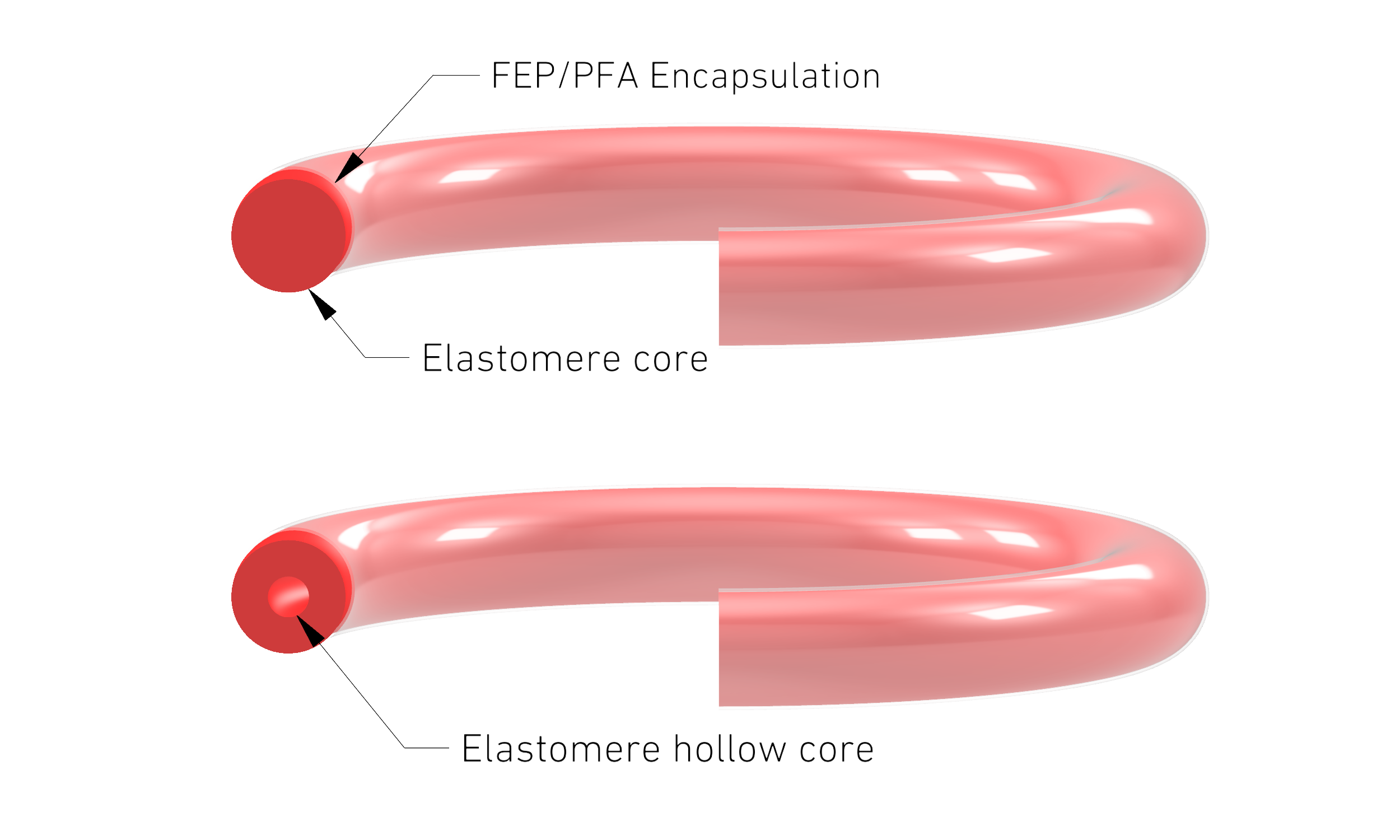

Static Seals FEP/PFA encapsulated O-ring

FEP/PFA encapsulated O-rings come in the same dimensions as elastomer O-rings and have similar installation parameters. It provides a good chemical resistance and due to its physiological harmlessness and sterilizability it is oftenly used in the chemical industry, petrochemistry as well as in the medicine and food industry.

FEP/PFA encapsulated O-ring

- high resistance against aggressive media

- high-performance in critical applications

- wide operating temperature range

- cost-effective

- physiological harmlessness, sterilisability

- for use in the food, chemical and petrochemical industries

- FDA-compliancy

- low coefficient of friction

- low permeation

Field of application

FEP/PFA encapsulated O-rings are used in many various technical areas. Especially where the application range of conventional O-rings has been exhausted.

On account of the good chemical resistance, physiological harmlessness and the fact that they can be sterilised, they are widely used in the chemical and petrochemical, food and medical industries.

The FEP/PFA O-ring should not be used in applications with abrasive contact surfaces or abrasive media, as these can destroy the encapsulation.

Main fields of application:

- axial-static sealing

- radial-static sealing

Technical values

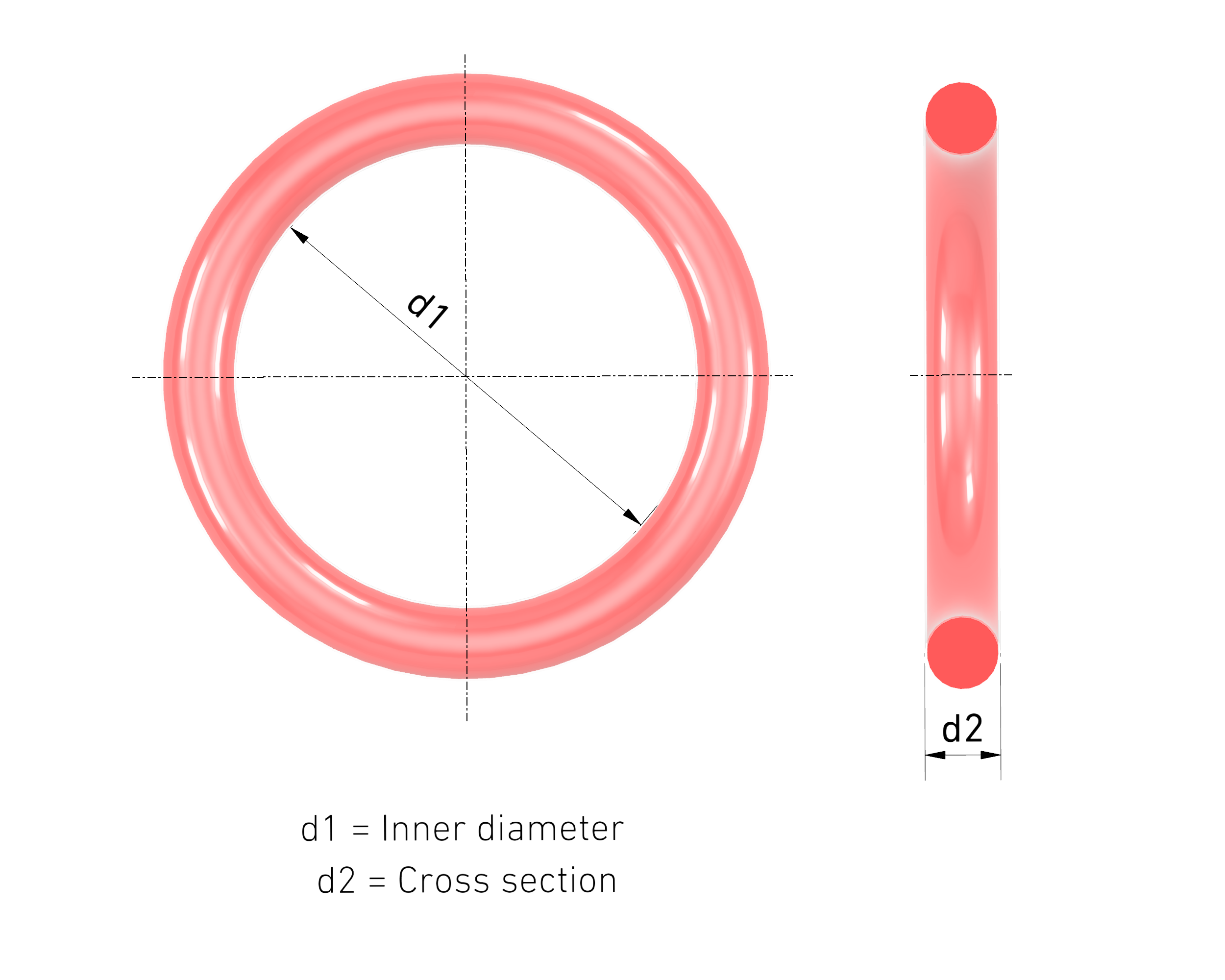

Definition of O-ring dimensions and ordering sizes

- Inside diameter d1 from approx. 6 mm to 5000 mm

- Cross section d2 from approx. 1,5 mm to 20 mm

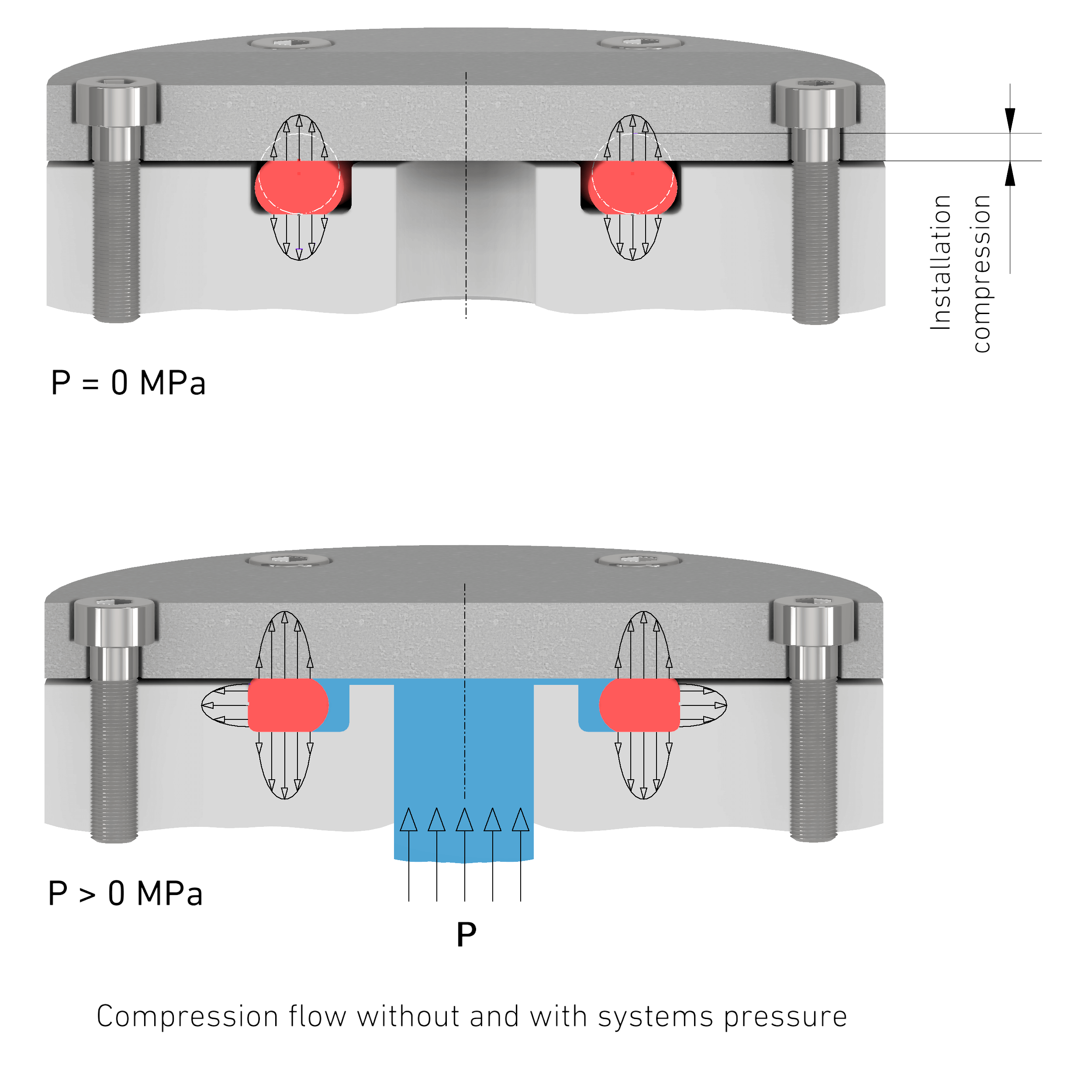

Sealing effect

The sealing effect of the FEP/PFA encapsulated O-ring results from the axial or radial compression of its cross section during installation, comparable to the elastomer O-ring. The elastomer core ensures an even pre-pressing through its elastic properties. However, due to the FEP/PFA encapsulation, the FEP/PFA O-rings have less elasticity.

Design Information

In general:

For the installation of FEP/PFA encapsulated o-rings, the same groove design applies as to standard elastomer O-rings.

Stretching/compression:

In contrast to elastomer O-rings, FEP/PFA encapsulated O-rings have limited stretch and compression due to their encapsulation.

Groove degree of filling:

The recommended maximum values are lower than for elastomer O-rings and depending on the application:

- static sealing 12 – 22%

Installation precompaction:

General requirements for the installation area:

- square groove

- low pressing forces into the housing

- limited O-ring stretch

When installing FEP/PFA encapsulated O-rings, the same recommendation apply regarding groove design and the corresponding installation dimensions as for elastomer O-rings.

For the installation of FEP/PFA o-rings, split grooves are recommended.

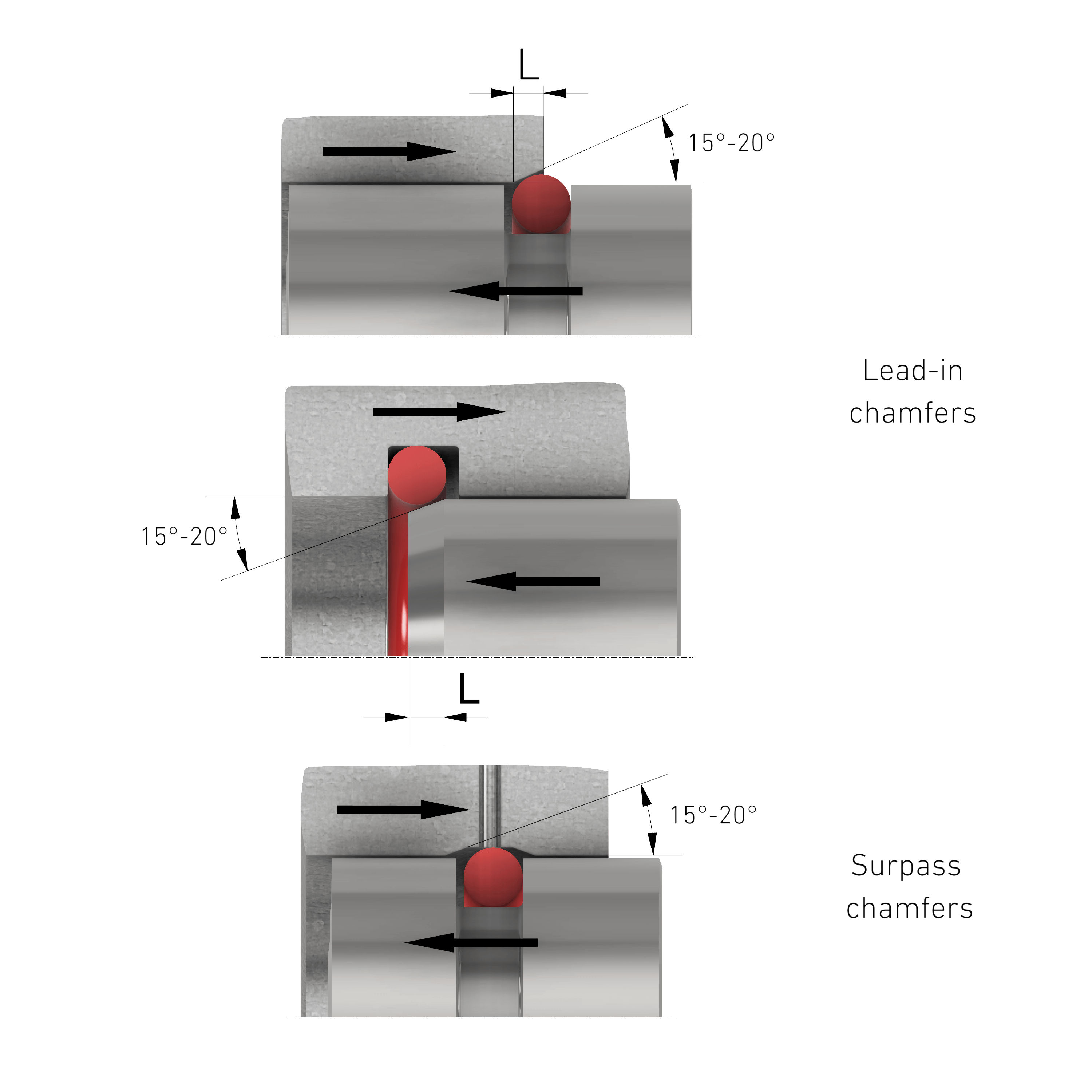

Installation Instructions

Correct assembly is crucial for the sealing function of the FEP/PFA encapsulated O-rings.

- The contact surfaces of the installation area must not be damaged by scratches, dents or similar.

- Edges and insert inclinations must be deburred as per guidlines

- Heat the O-ring in hot, compatible media before assembly

- Install the O-ring immediately after heating, it is easier to deform

- The O-ring must not be buckled or overstretched

Technology - General sealing topics, special constructions

Our Logistics – Your Service

Innovative, environmentally friendly and efficient

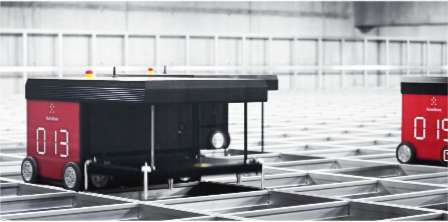

In addition to innovative techniques, our logistics has 2,870 sqm of process surface. We have the world's first AutoStore storage system on two levels. Both grits are connected to each other by means of special lifters. In total, up to 31,000 containers can be stored in a very confined space. Due to this subdivision, up to 240,000 storage areas can be managed most efficiently.