Static Seals PTFE O-ring

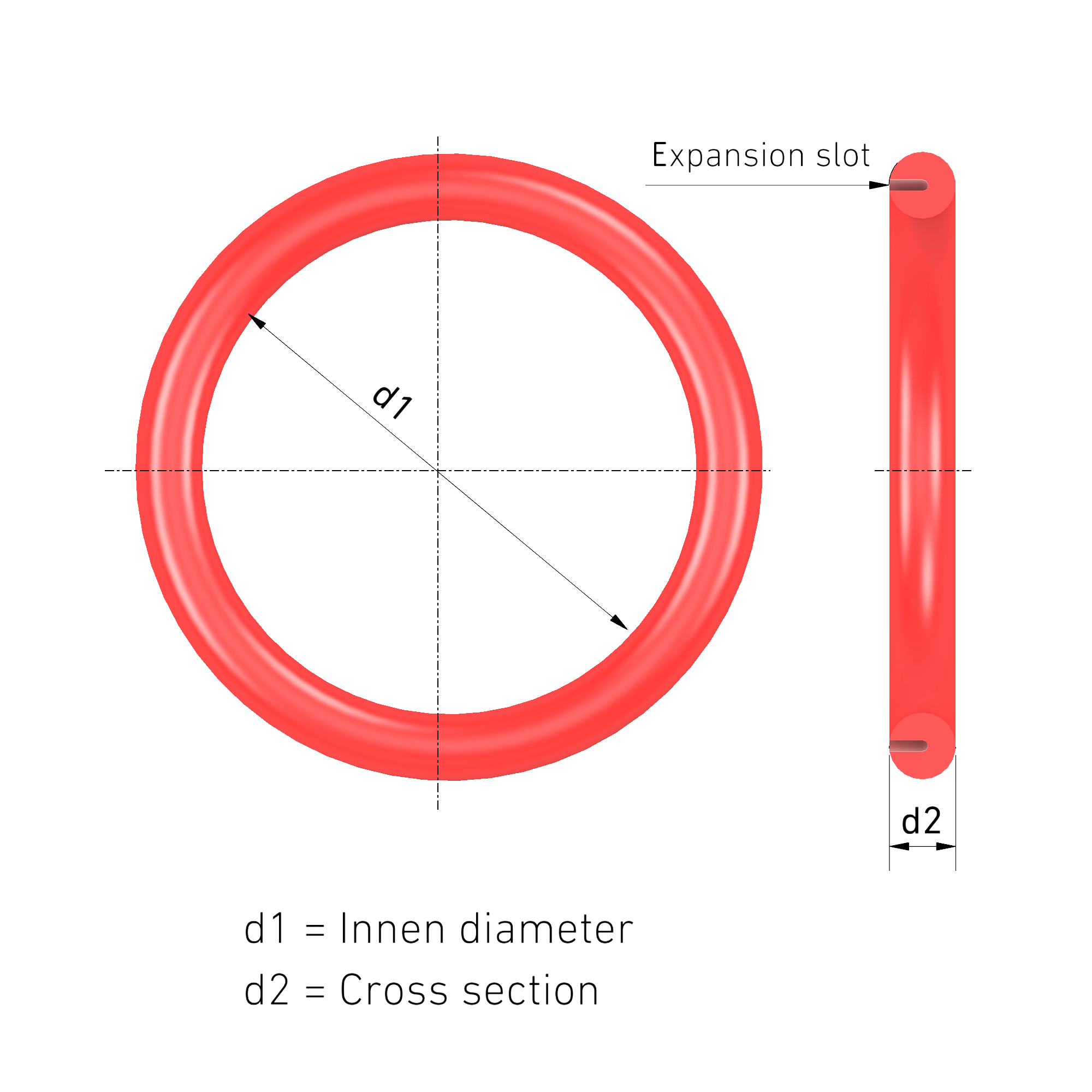

A PTFE O-ring is an endless round ring that has a circular cross section and is predominantly used as an axial static seal. By pressing the cross section during installation, the sealing effect comes into play. Since PTFE has a negligible elastic behavior, an expanding slot has been incorporated around the circumference. This side has to permanently face the pressure side.

PTFE O-rings are always used when the general elastomer O-ring cannot withstand the needed resistance for thermal or chemical applications. Due to good chemical resistance, physiological harmlessness and sterilizability, PTFE O-rings are widely used in the chemical industry, petrochemistry as well as in the medicine and food industry.

PTFE O-ring

- high chemical resistance

- Temperature resistance from -200°C up to +260°C

- good gliding properties

- physiological harmlessness, sterilisability

- for use in the food, chemical and petrochemical industries

- low coefficient of friction

Field of application

PTFE O-rings are used wherever the usual elastomer O-rings can no longer withstand the thermal and chemical requirements. PTFE can be used with almost all media. The only restrictions are with liquid alkali metals and some fluorine and halogen compounds. Due to their excellent chemical resistance, physiological harmlessness and sterilisability, they can be found in the petrochemical, food, chemical and pharmaceutical industries.

Main fields of application:

- static sealing – between flanges, housing parts and covers

Operating parameters:

To ensure a reliable sealing function, the operating parameters and their limit values must be checked as a whole

Technical values

Definition of O-ring dimensions and ordering sizes

• Inside diameter d1 from approx. 3 mm

• Cross section d2 from approx. 0,5 mm to 12 mm

Sealing effect

The sealing effect of the PTFE O-Ring results from the compression of its cross section during installation. To increase elasticity, the integrated expansion slot must always be located on the side of pressure.

Installation Instructions

In general:

General specifications regarding constructive design and surface qualities can be adapted from the elastomer O-rings.

Stretching/compression:

PTFE O-rings have very limited stretch and compression properties. Due to the low elasticity, the cross section of the O-ring is practically identical to the depth of the groove base.

Installation area:

General requirements for the installation area:

- The installation must be carried out in easily accessible, split grooves.

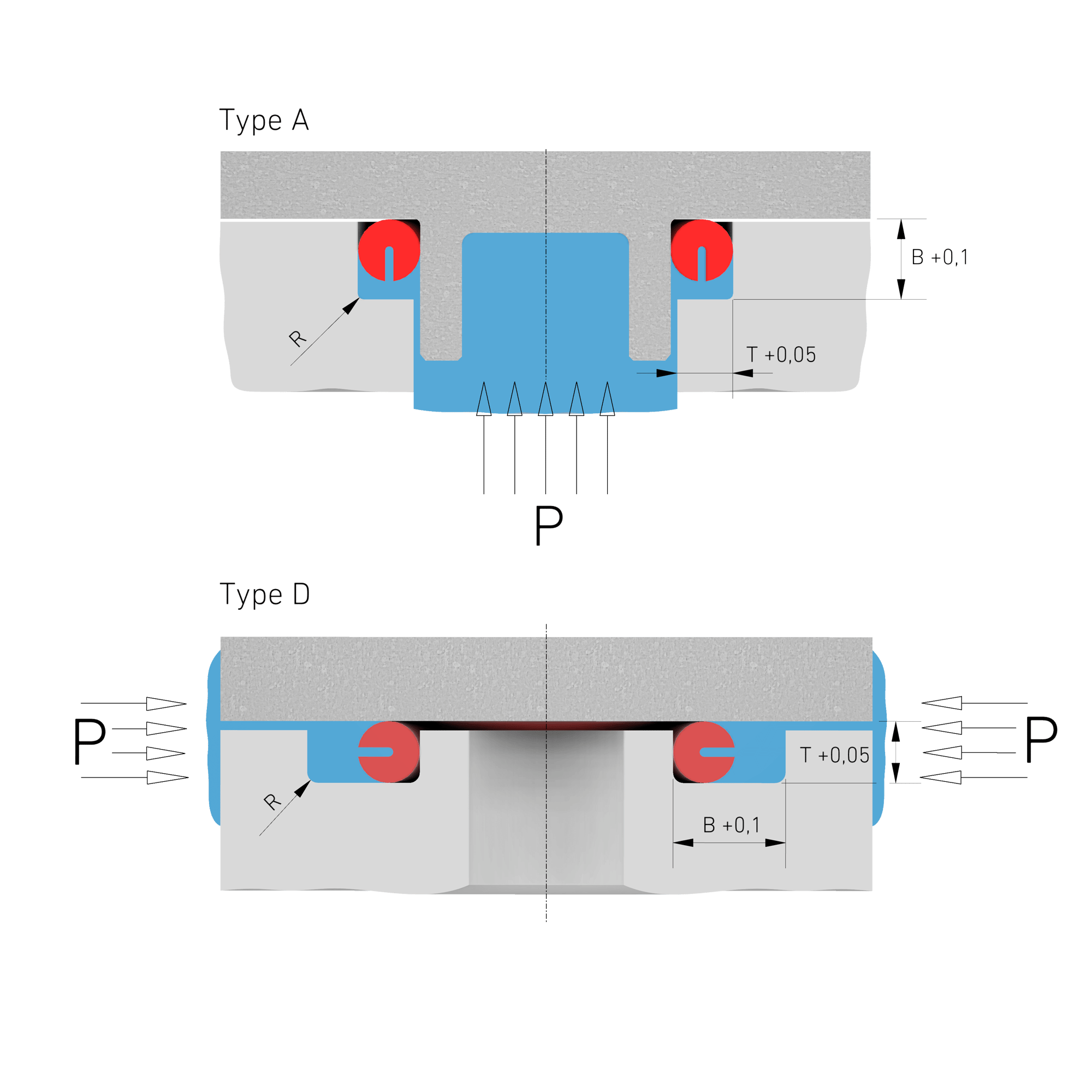

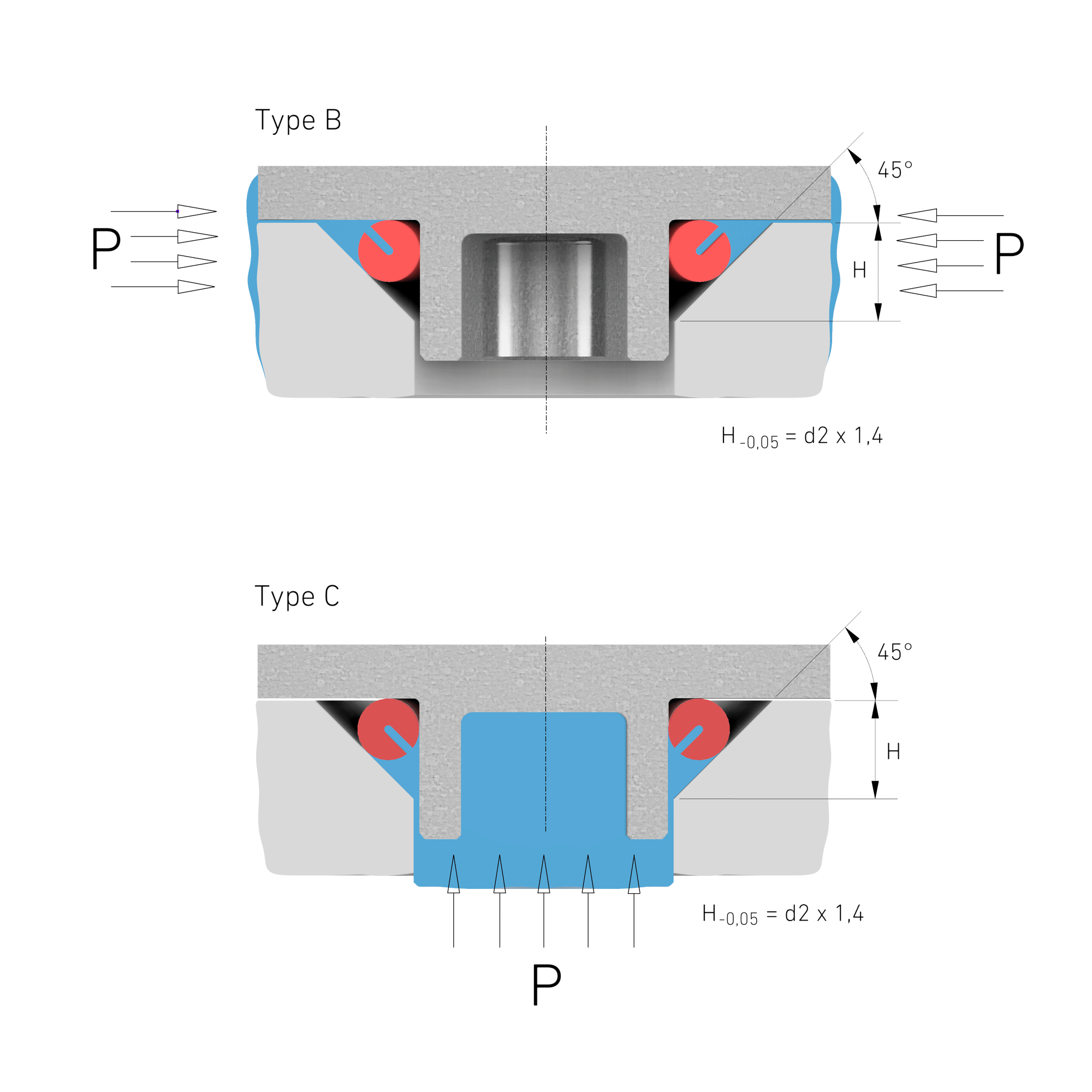

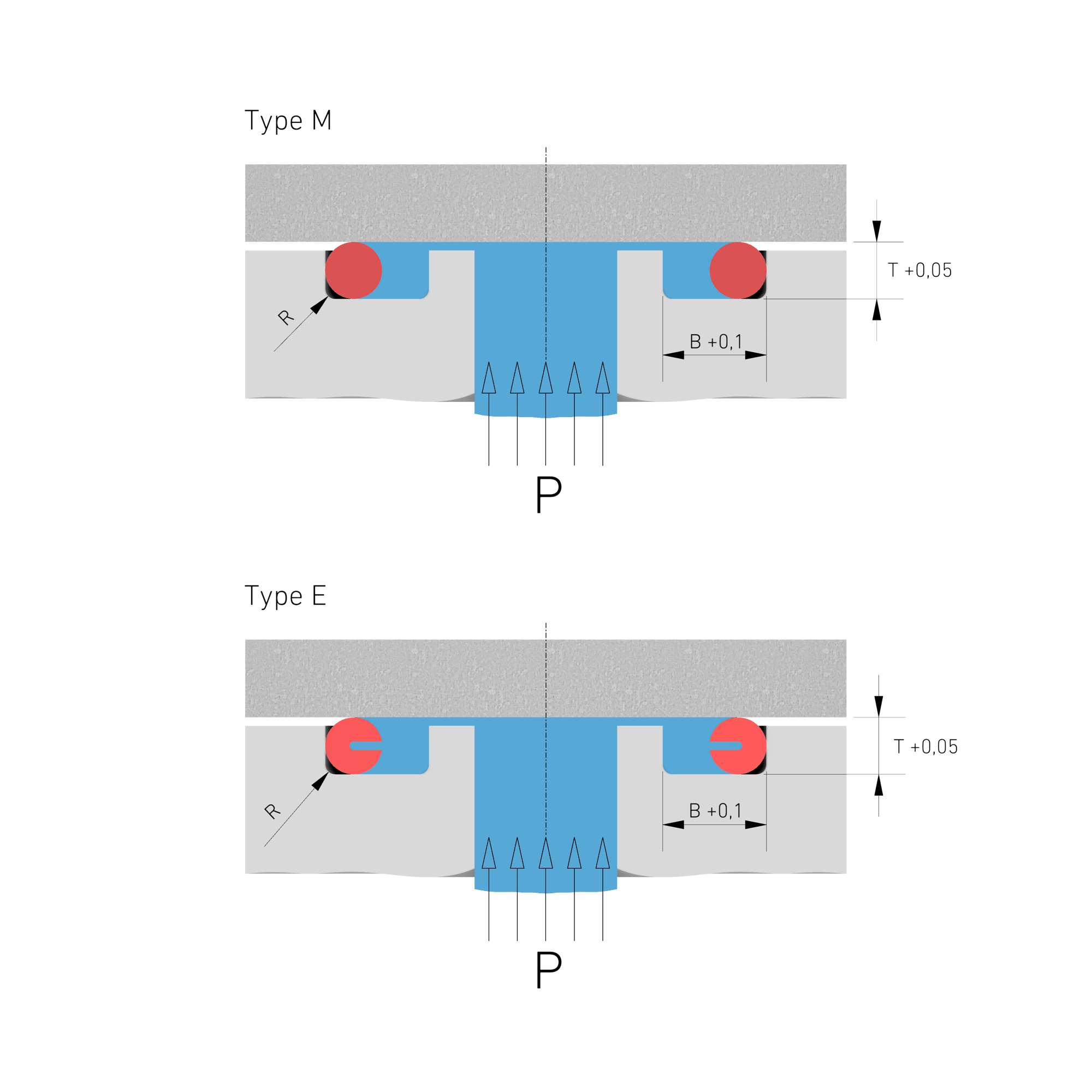

Installation recommendation

The different installation designs are shown with the corresponding O-ring types. The expansion slot is always located on the pressure side. Design types B & C with the triangular groove, must be avoided due to the undefined position.

Technology - General sealing topics, special constructions

Our Logistics – Your Service

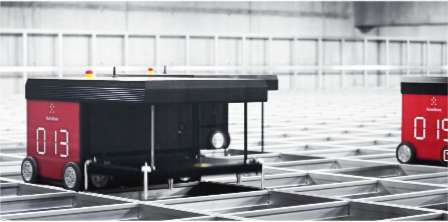

Innovative, environmentally friendly and efficient

In addition to innovative techniques, our logistics has 2,870 sqm of process surface. We have the world's first AutoStore storage system on two levels. Both grits are connected to each other by means of special lifters. In total, up to 31,000 containers can be stored in a very confined space. Due to this subdivision, up to 240,000 storage areas can be managed most efficiently.