Static Seals Special Design

Moulded parts are individually designed sealing elements, that have been specially manufactured to customer specifications. They are the ideal solution for a specific sealing application. They are often designed as static sealing elements for housings and assure that no dirt or moisture can penetrate into the system. They ensure for a reliable and durable sealing. Special parts can also be developed as a dynamic highly stressed sealing that provide the most demanding conditions for a reliable and durable sealing.

Moulded parts can be produced in all established elastomeric material combinations or also as a rubber to metal bonding design, these are usually tool dependent. Special parts made of plastics can be produced in different techniques. The common method is turned parts when made of PTFE materials or per injection moulding for thermoplastic polymer or thermoplastic elastomer parts. There are different types of manufacturing techniques with tooling, for example:

- Compression moulding

- Injection moulding

Special Design

Technical values

Technology - General sealing topics, special constructions

Head of Engineering

Our Logistics – Your Service

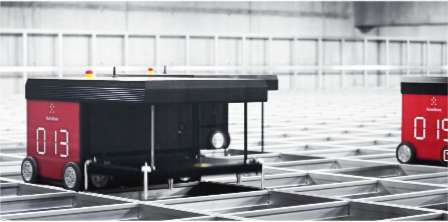

Innovative, environmentally friendly and efficient

In addition to innovative techniques, our logistics has 2,870 sqm of process surface. We have the world's first AutoStore storage system on two levels. Both grits are connected to each other by means of special lifters. In total, up to 31,000 containers can be stored in a very confined space. Due to this subdivision, up to 240,000 storage areas can be managed most efficiently.