Static Seals Square Ring

A Square Ring is a double-acting axial static sealing element, which is a good alternative to the classic O-ring. Due to its square profile, it only gets minimally deformed when put under pressure. This sealing element is very insensitive towards gap extrusion, no Back-up Ring is necessary even at high pressures and it does not twist during installation.

Square Rings are ideal for sealing flanges, valves, plates and fasteners and are available in a variety of common elastomer materials. The most common of these would be NBR, FKM, EPDM, CR, VMQ and FVMQ. Dimensions are available according to AS 568 (inch sizes).

Square Ring

- good alternative to an O-ring

- insensitive to gap extrusion

- additional Back-up ring is rarely required

- high sealing tightness despite low compression

- no twisting during assembly

- sturdy at high pressures

Main fields of application

- axial-static sealing - between flanges, valves, plates and covers

Operating parameters

To ensure a reliable sealing function, the operating parameters and their limit values must be checked as a whole.

Technical values

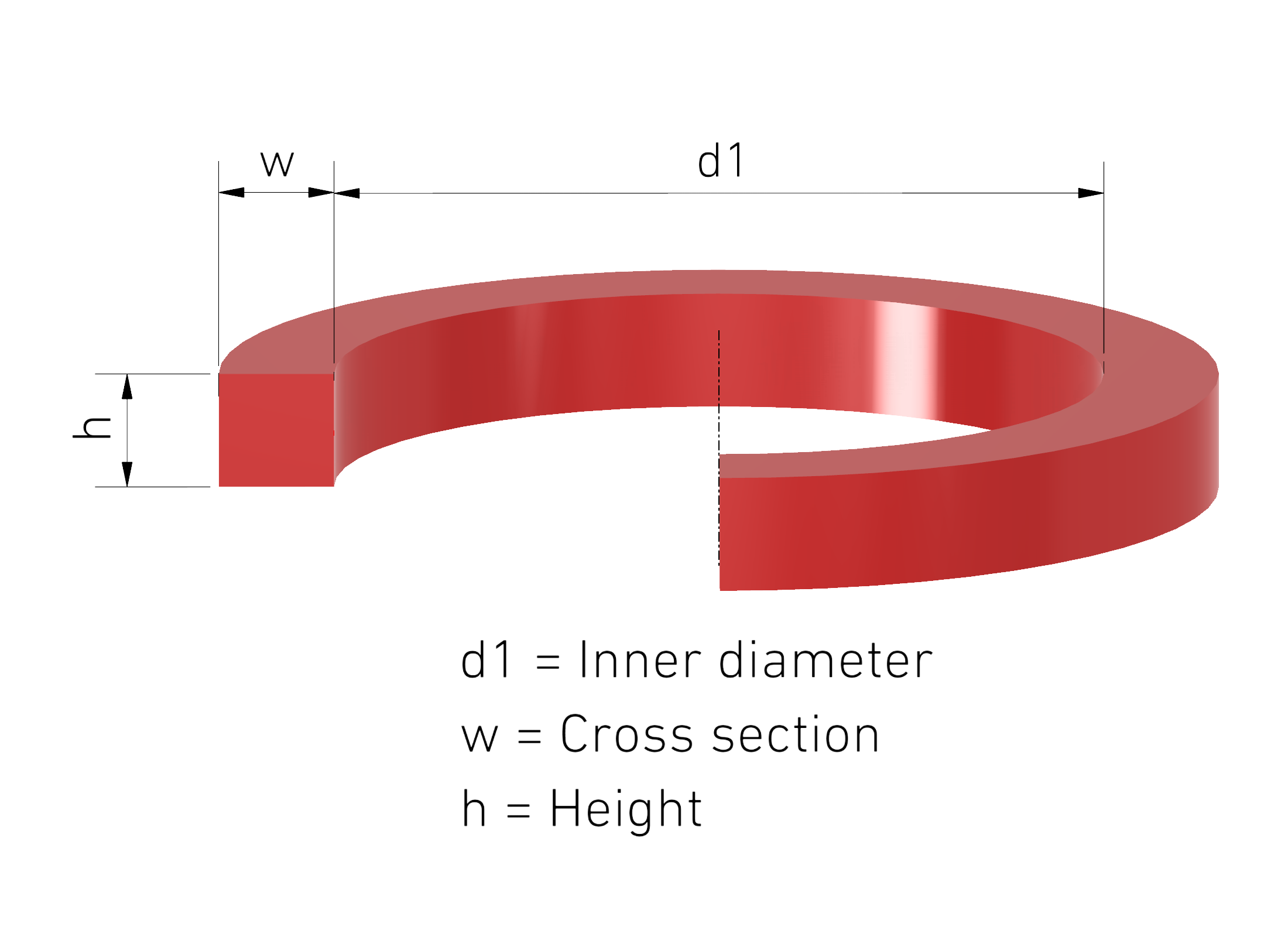

Definition of Square ring dimensions and ordering sizes

- Inner diameter d1 from approx. 4,42 mm to 456,07 mm

- Cross section w and height h from approx. 1,68 mm to 5,16 mm

Sealing effect

The sealing effect of the Square ring is the result of the axial or radial compression of the rings cross section when it is installed. Due to its profile and better distribution of the pressure, a high sealing effect is achieved. The system pressure additionally increases the pressure on the sealing surfaces.

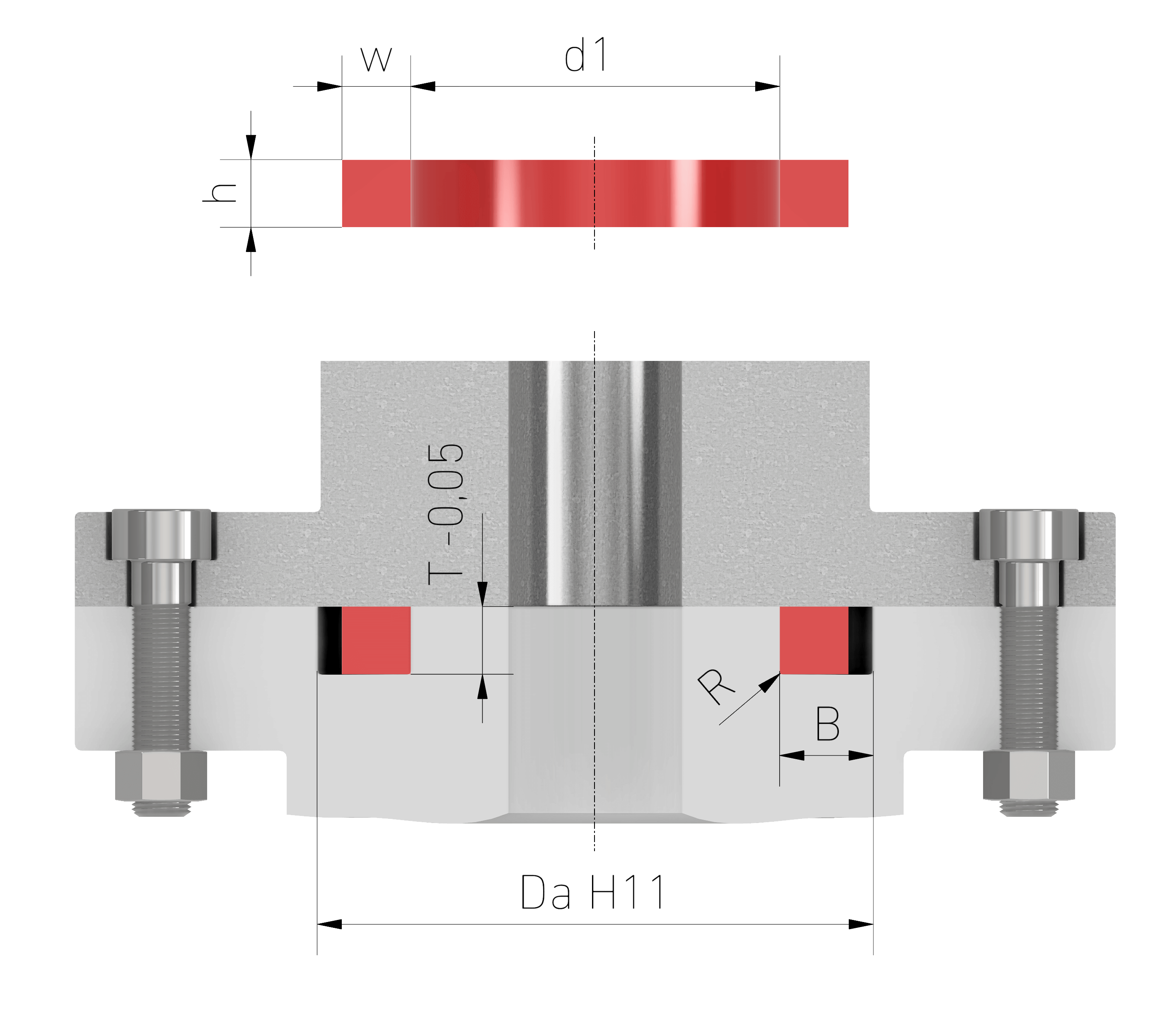

Design information

In general

Square rings are to be installed in rectangular grooves. All edges of the groove must be burr free.

Groove filling

When compressed, the filling level of the groove with the inserted rectangular ring must not be higher than 80%. For special applications such as vacuum, please contact our application consultants.

Surface quality

In order to achieve an optimum sealing effect, the contact surfaces must meet minimum requirements. The permissible roughness values must be adhered to, especially in pulsating pressure applications.

Technology - General sealing topics, special constructions

Head of Engineering

Our Logistics – Your Service

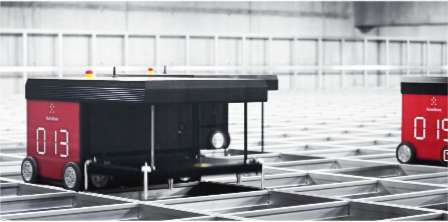

Innovative, environmentally friendly and efficient

In addition to innovative techniques, our logistics has 2,870 sqm of process surface. We have the world's first AutoStore storage system on two levels. Both grits are connected to each other by means of special lifters. In total, up to 31,000 containers can be stored in a very confined space. Due to this subdivision, up to 240,000 storage areas can be managed most efficiently.