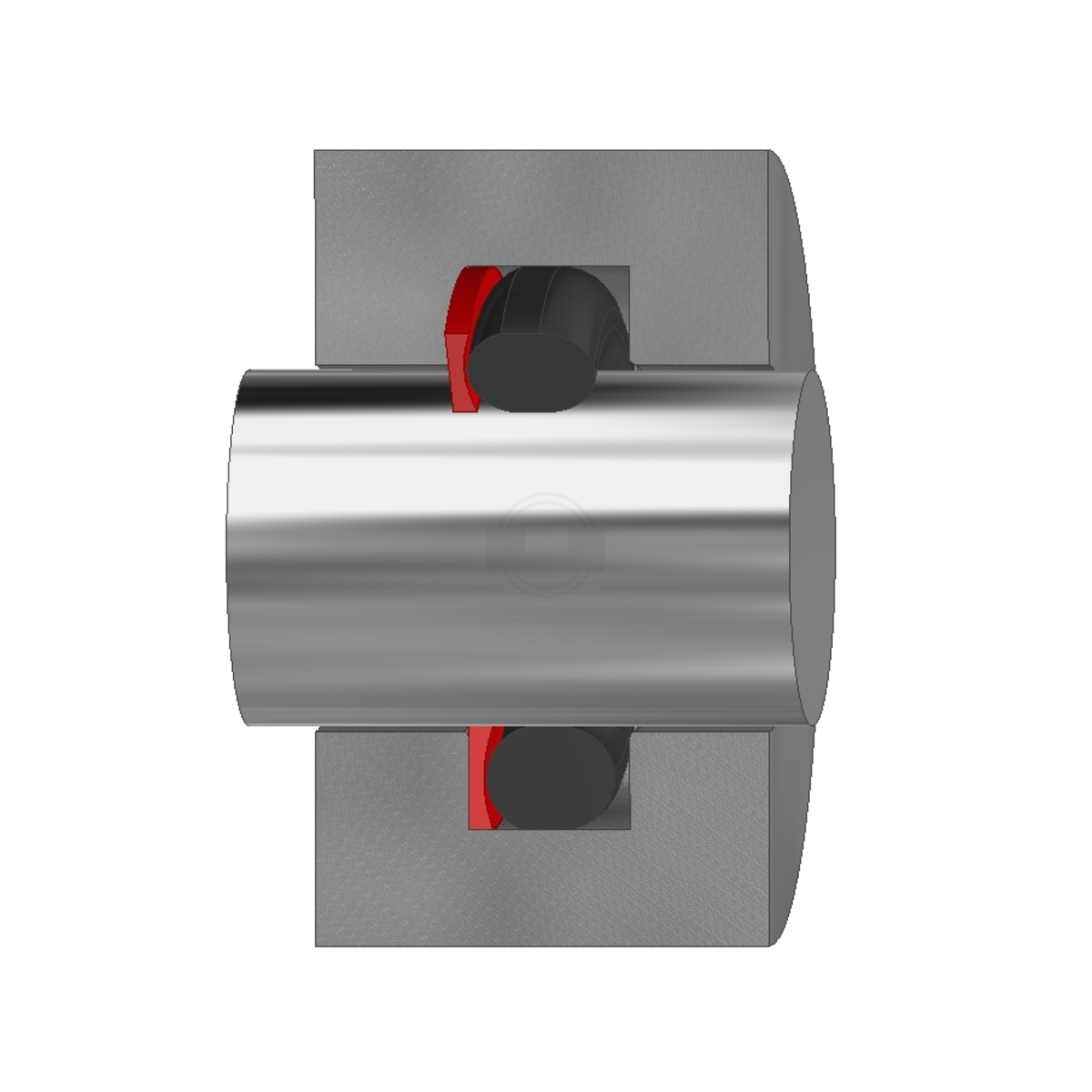

Static Seals Back-up Ring BE – concave unslotted

The Back-up Ring BE has a closed profile with a concave groove. Due to its assembly ease and elasticity, it is particularly suitable for all installations. It has a very good O-ring support at very high und pulsating pressures through the concave design.

Back-up Rings are exactly adapted to the groove height. The required groove width increases by the width of the Back-up Rings. BE Back-up Rings are produced per injection moulding. Standard materials are NBR and FKM, other compounds are available upon request.

Back-up Ring BE - concave unslotted

Technical values

linear up to 20 MPa

linear up to 10 MPa

Technology - General sealing topics, special constructions

Head of Engineering

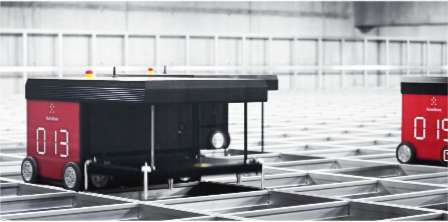

Our Logistics – Your Service

Innovative, environmentally friendly and efficient

In addition to innovative techniques, our logistics has 2,870 sqm of process surface. We have the world's first AutoStore storage system on two levels. Both grits are connected to each other by means of special lifters. In total, up to 31,000 containers can be stored in a very confined space. Due to this subdivision, up to 240,000 storage areas can be managed most efficiently.