Static Seals U-ring Type UH

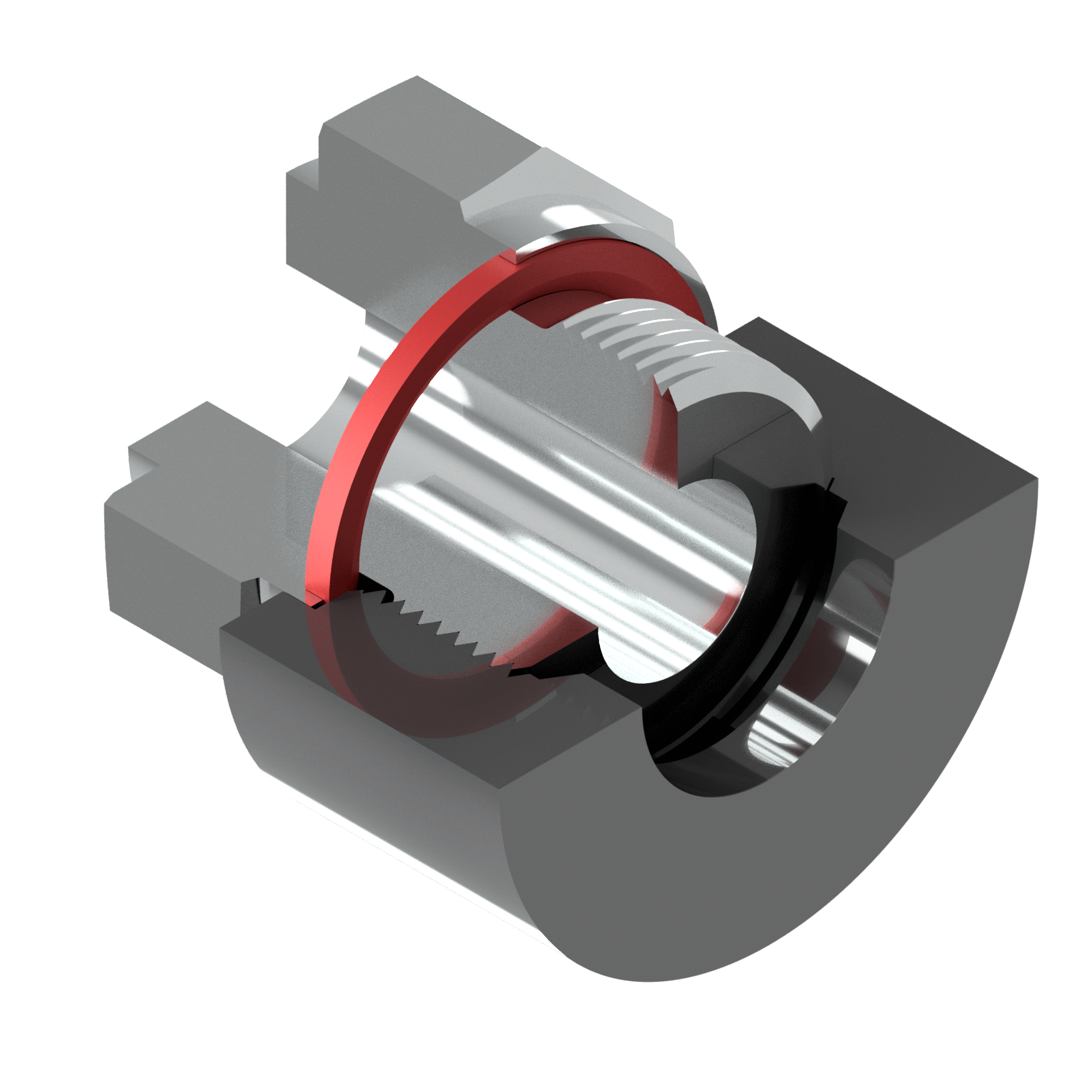

The UH profile rings are fluid connector seals. These consist of a pure elastomer seal according to the DIN EN ISO 1179-2 (imperial) and DIN EN ISO 9974-2 (metrical), former DIN 3869. By compressing the elastic sealing profil ring, the sealing element is pressed into the installation space and seals between the two flat surfaces of the components to be joined.

The UH is available in a variety of common elastomer materials. The most common of these would be NBR, FKM and EPDM.

U-ring Type UH

- application in high pressures

- simple and fast assembly

- standardized dimsensions

Fields of application

Elastomeric profile sealing rings according to the DIN EN ISO 1179-2 and DIN EN ISO 9974-2 (former DIN 3869) for sealing connecting elements and screw-in sockets. Groove dimensions according to the DIN 3852 Part 11.

Main fields of application:

- axial-static sealing

Technical values

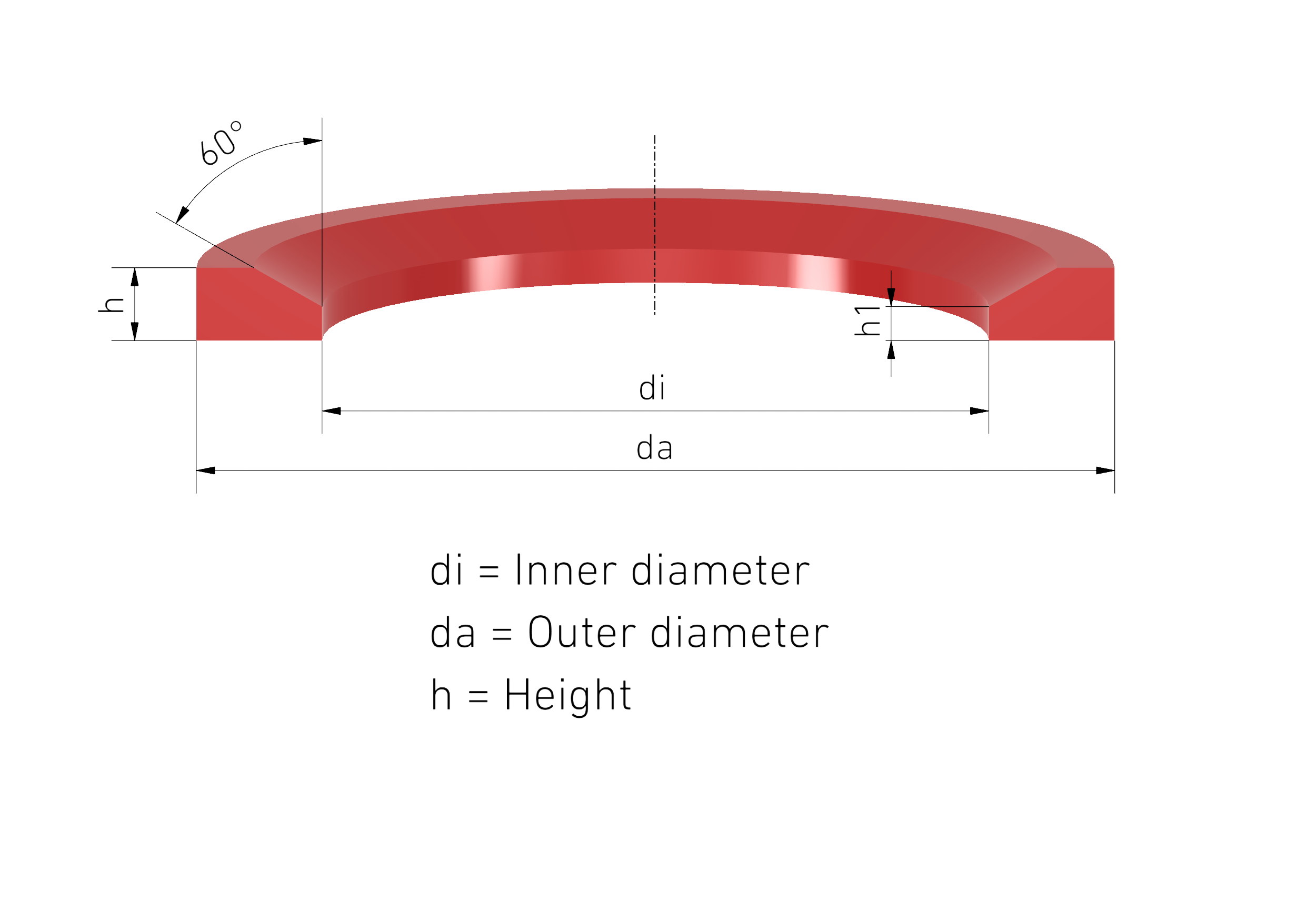

Definition of UH-ring dimensions and ordering sizes

- Inch and metric thread sizes according to DIN EN ISO 1179-2 or DIN EN ISO 9974-2 (formerly DIN 3869).

Sealing effect

The sealing effect of the UH-ring is the result of the axial compression of the ring when it is installed. The system pressure additionally increases the pressure on the sealing surfaces.

Operating parameters

For a reliable sealing function, the following application parameters and their limit values must be checked in relation to each other.

Design information

Installation of the seal is to be in a screw connection groove or a screw-in socket, specified in accordance with DIN 3852 Part 11. Process pressures to be max. 63 MPa depending on the material.

Attention: U-rings are not suitable for securing screws!

Assembly instructions

To exclude possible sources of error, ensure that the following points are observed for the sealing function when installing UH-rings:

- defined insert inclinations, burr free, rounded-off transition

- surface quality Ra < 1,6 µm, Rmax < 6,3 µm

- burr-free rounded-off holes and slits

- damage caused by the thread must be avoided

- installation tools to pass over sharp edges and corners (e.g. threads)

- dirt-free sealing surface

- UH-ring must not be overstretched

Technology - General sealing topics, special constructions

Head of Engineering

Our Logistics – Your Service

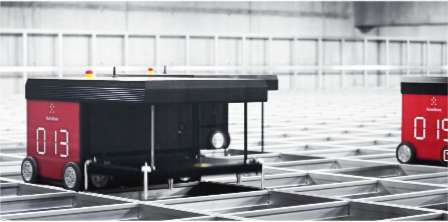

Innovative, environmentally friendly and efficient

In addition to innovative techniques, our logistics has 2,870 sqm of process surface. We have the world's first AutoStore storage system on two levels. Both grits are connected to each other by means of special lifters. In total, up to 31,000 containers can be stored in a very confined space. Due to this subdivision, up to 240,000 storage areas can be managed most efficiently.